Fan speed offset explained: Beat frequency theory and how to further optimise acoustics

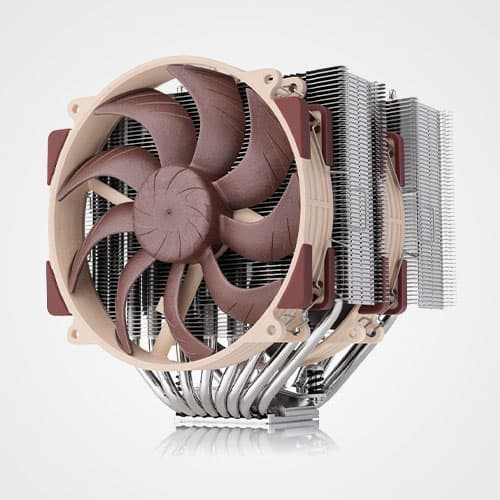

When two fans are running at almost the same, constant speed in a push-pull configuration or, albeit to a lesser extent, side by side, their acoustic interaction can lead to undesirable harmonic phenomena such as intermittent vibrations or periodic humming due to interference, which can be heard as beat frequencies. Therefore, the two fans (models PPA and PPB) contained in the NF-A12x25 G2 and NF-A14x25 G2 Sx2-PP dual fan sets as well as with the NH-D15 G2 CPU cooler are slightly offset in speed in order to avoid such phenomena. With one fan running ~50rpm slower (PPA) and one ~50rpm faster (PPB) in the case of the NF-A12x25 G2 fans, and ~25rpm slower (PPA) and one ~25rpm faster (PPB) in the case of the NF-A14x25(r) G2 fans, the overall cooling performance can be kept the same while efficiently preventing intermittent vibrations or periodic humming. Since the perception of beat frequencies can vary depending on psychoacoustic preferences, users can easily further optimise acoustics by slowing the PPA fan down a little more through PWM control or the supplied Low-Noise Adaptor, which will result in an even smoother sound signature due to the increased offset.

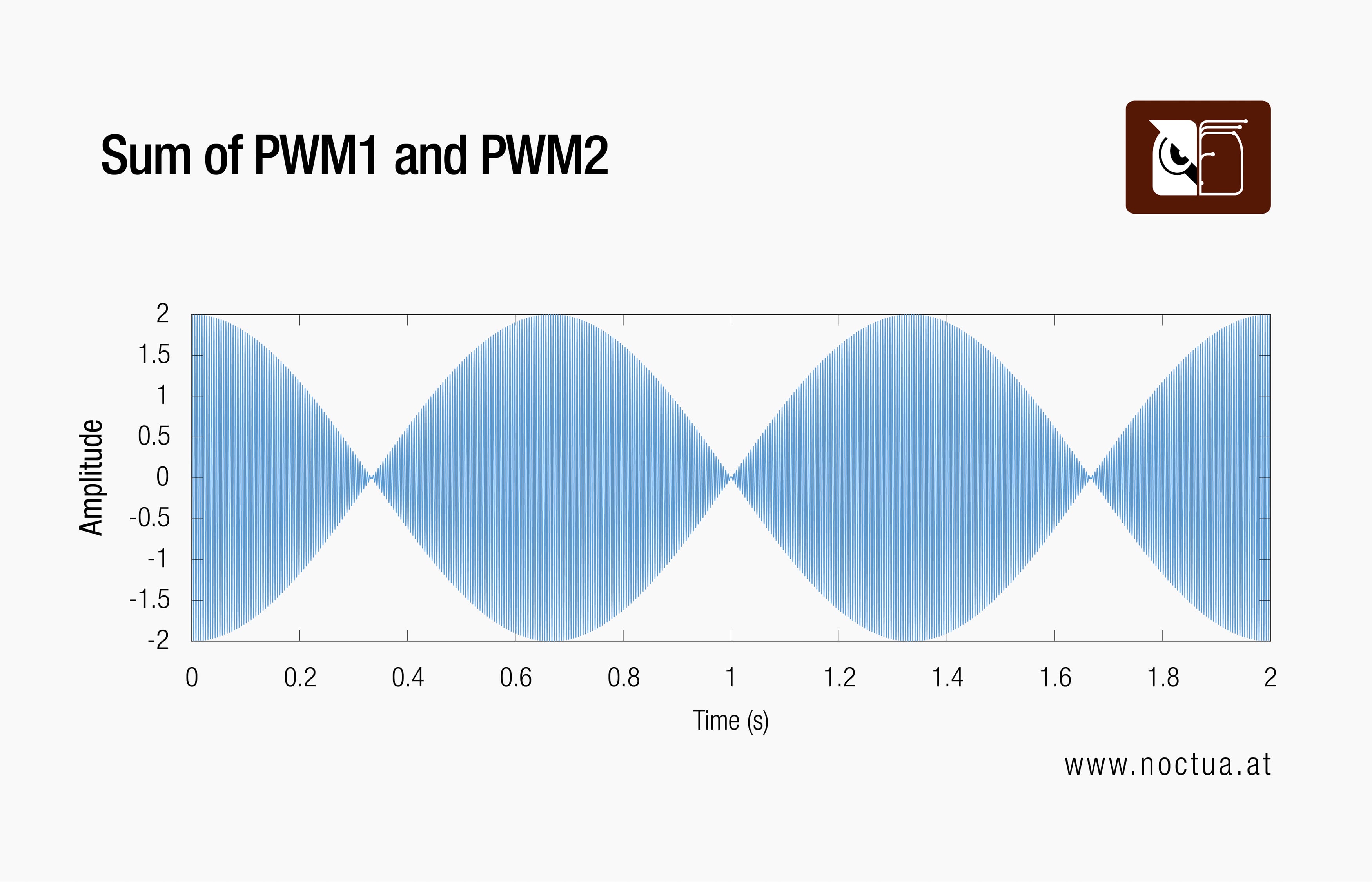

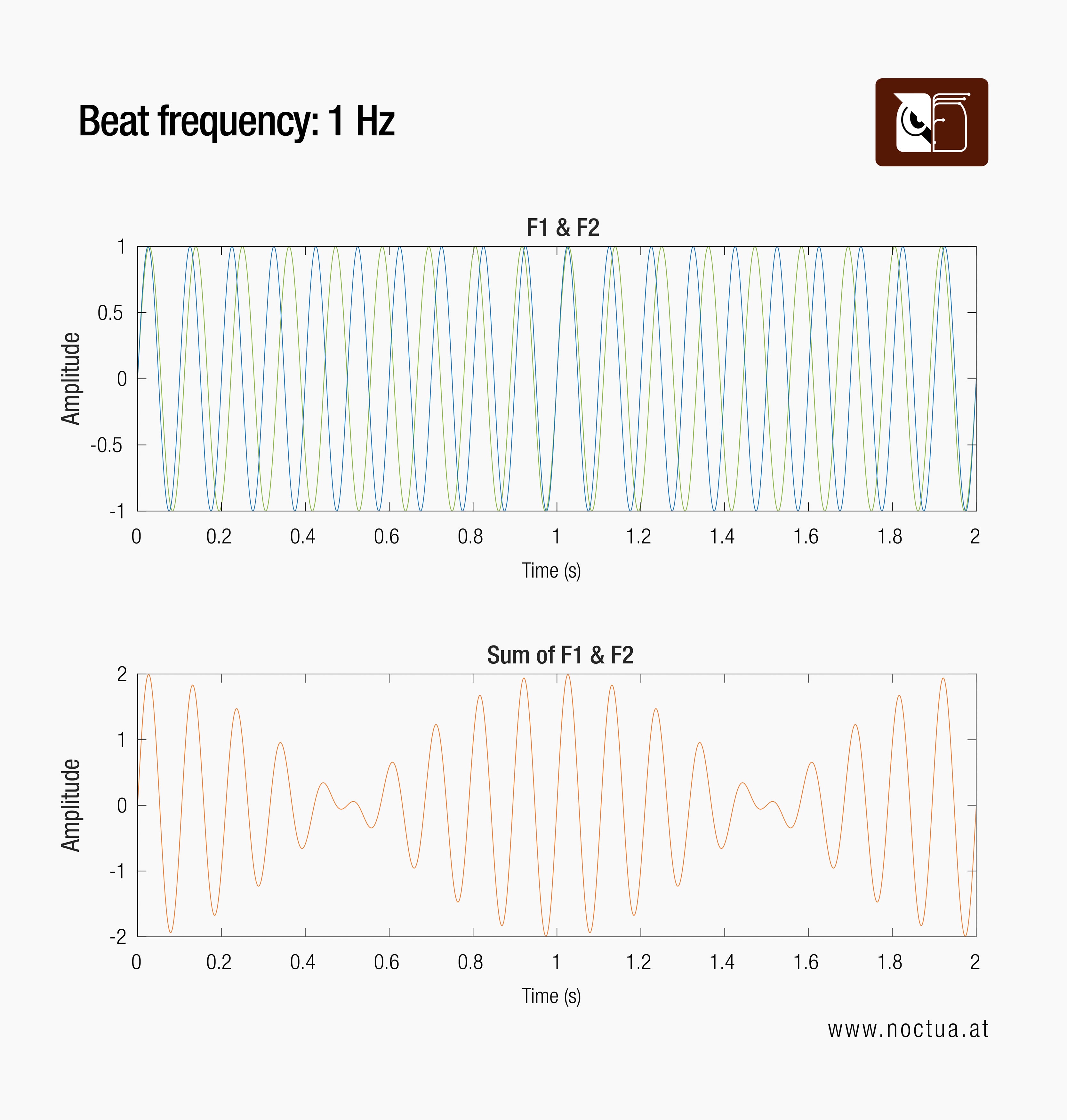

Beat frequencies are an acoustic phenomenon that occurs when two sounds of very similar characteristics interfere. The interference of the two sounds is audible as a modulated tone due to the sounds shifting in and out of phase, alternating between constructive and destructive interference. As the two sounds shift in and out of phase, their combined amplitude will rise and fall, which causes the resulting tone to periodically vary in volume, like a beat. The rate of this variation is called beat frequency, and it is the difference between the two original frequencies. For example, if two waves with frequencies of 10 and 9 Hz are superimposed, they will create a beat frequency of 1 Hz:

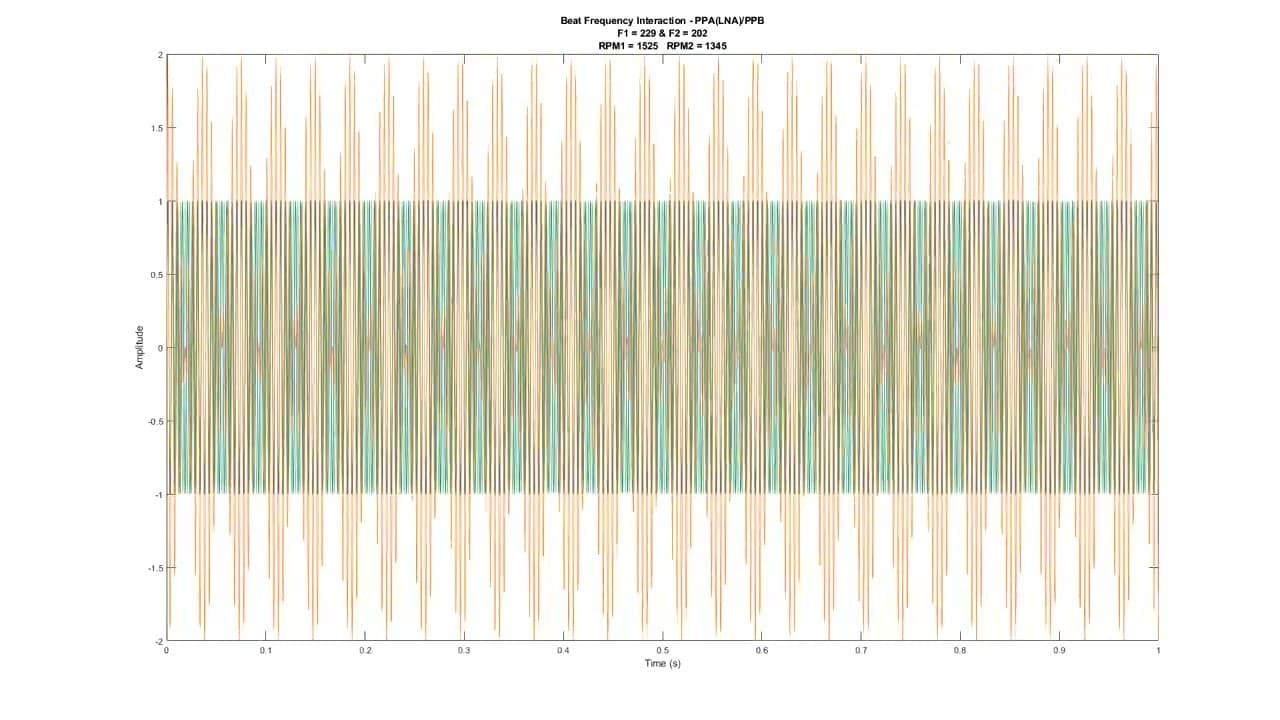

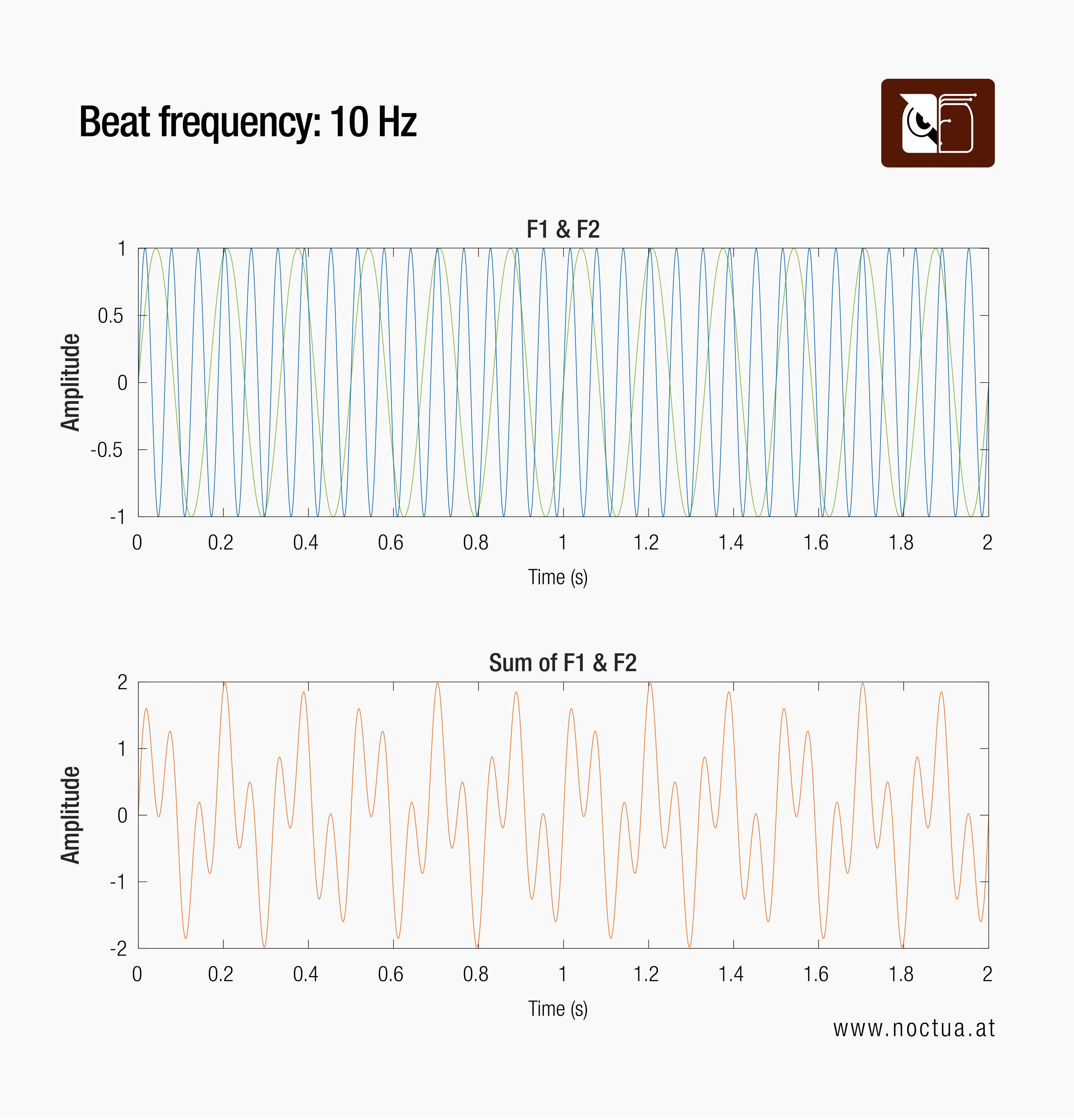

The beat frequency will become slower the closer the two original frequencies are to each other and disappear altogether if they are completely identical, resulting in a non-modulated superimposition that will be the combined amplitude of the two original tonal noises. Conversely, the beat frequency will get faster the bigger the difference in frequency between the original sounds becomes. The following example shows the much faster 10 Hz beat frequency that results from the combination of a 6 Hz and a 16 Hz signal:

The faster the modulation of the beat frequency becomes, the more difficult it becomes for the human hearing to register the variations in volume: The beat frequency will first be perceived as a tone of high roughness, which is typically less distracting, and then eventually blend into separate tones which do not sum to create a higher amplitude wave, which means that the beat frequency will no longer be audible at all. The exact point at which the beat frequency will no longer be audible and where the overall sound spectrum is considered smooth and pleasant depends on individual psychoacoustic preferences.

When advanced fans with extremely precise speed control such as the NF-A12x25 G2 PWM and NF-A14x25(r) G2 PWM models with SupraTorque™ functionality are running side-by-side or in push-pull at the same target speed, their speeds and acoustic spectrums are so close that beat frequencies can occur. This may be conceived as a periodic humming and, depending on the configuration, can also lead to intermittent vibrations that come and go as the sounds shift in and out of phase.

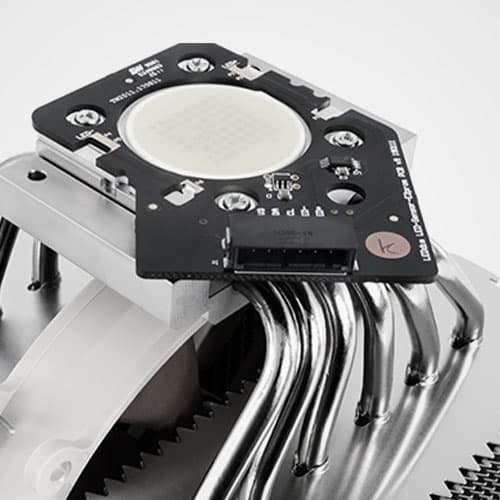

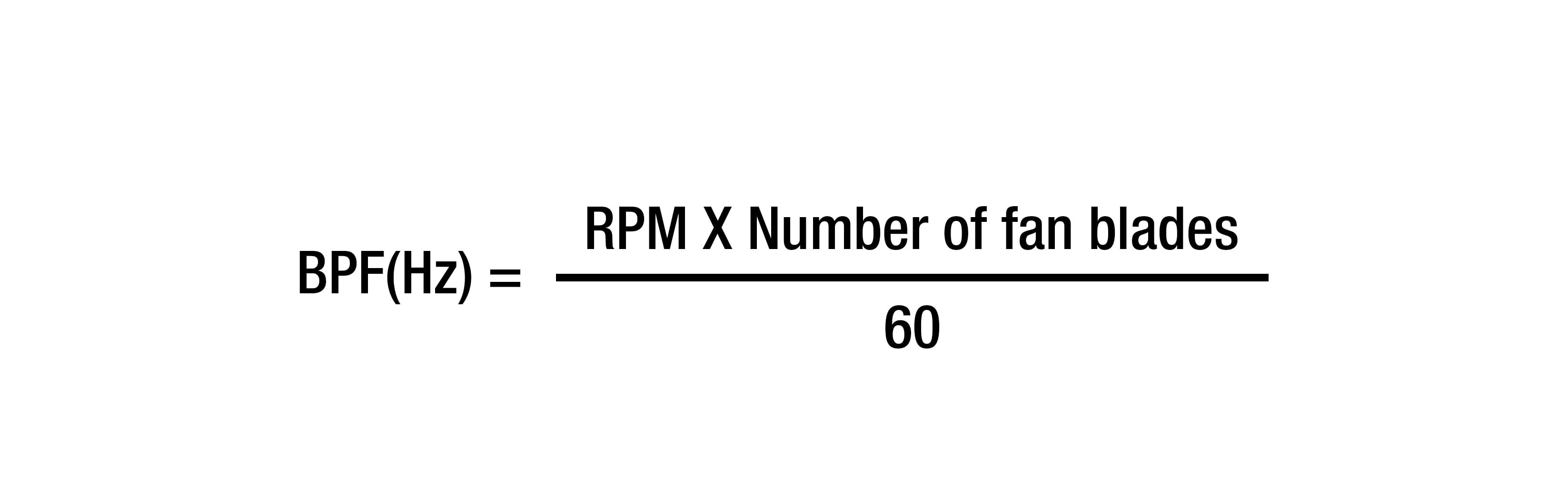

To demonstrate the beat frequency interaction between two fans, we must first calculate the Blade Passing Frequency (BPF), which is the main tonal noise that is produced when fans spin. Depending on the RPM and the number of fan blades, the BPF can be calculated using the following formula:

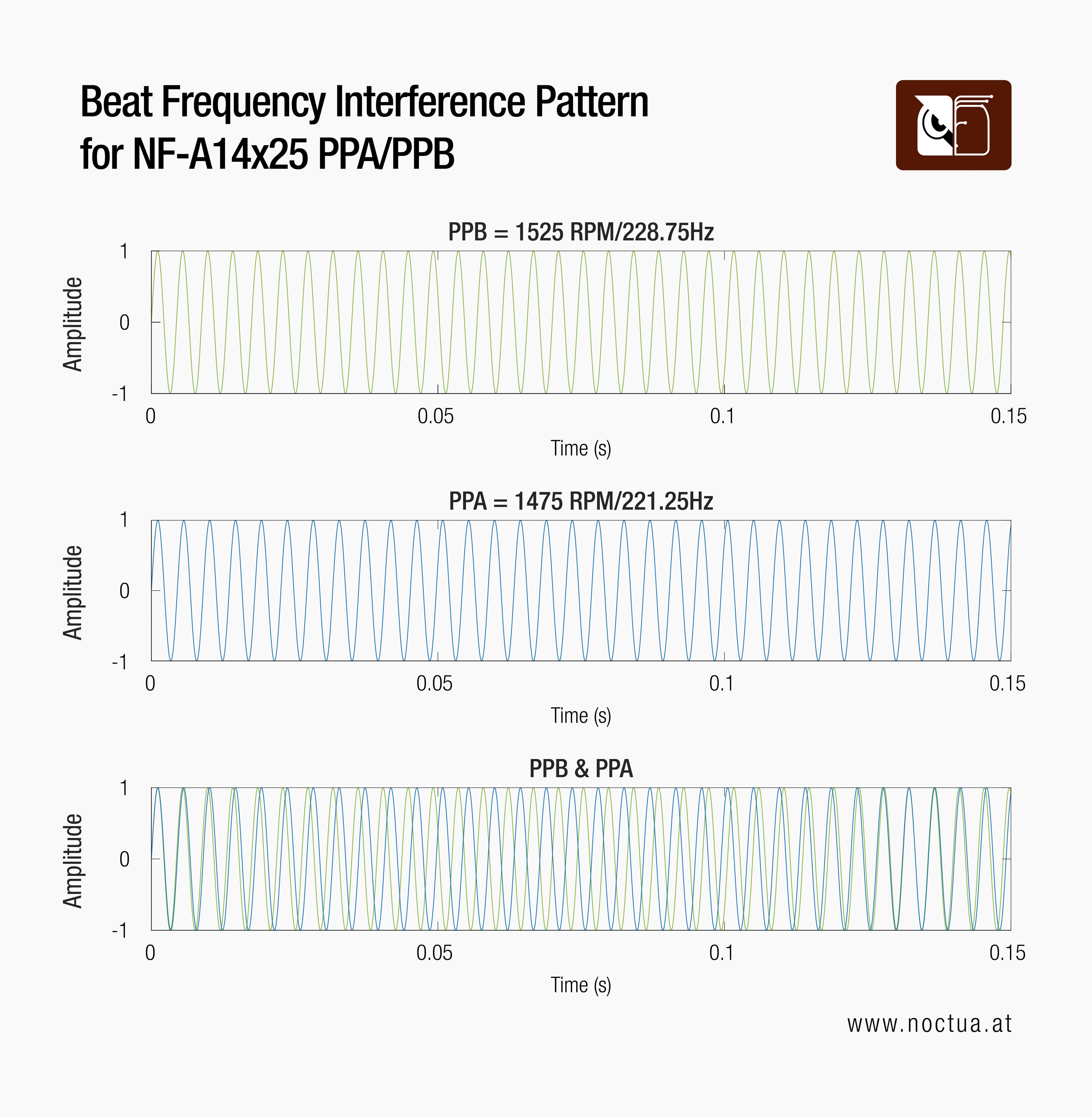

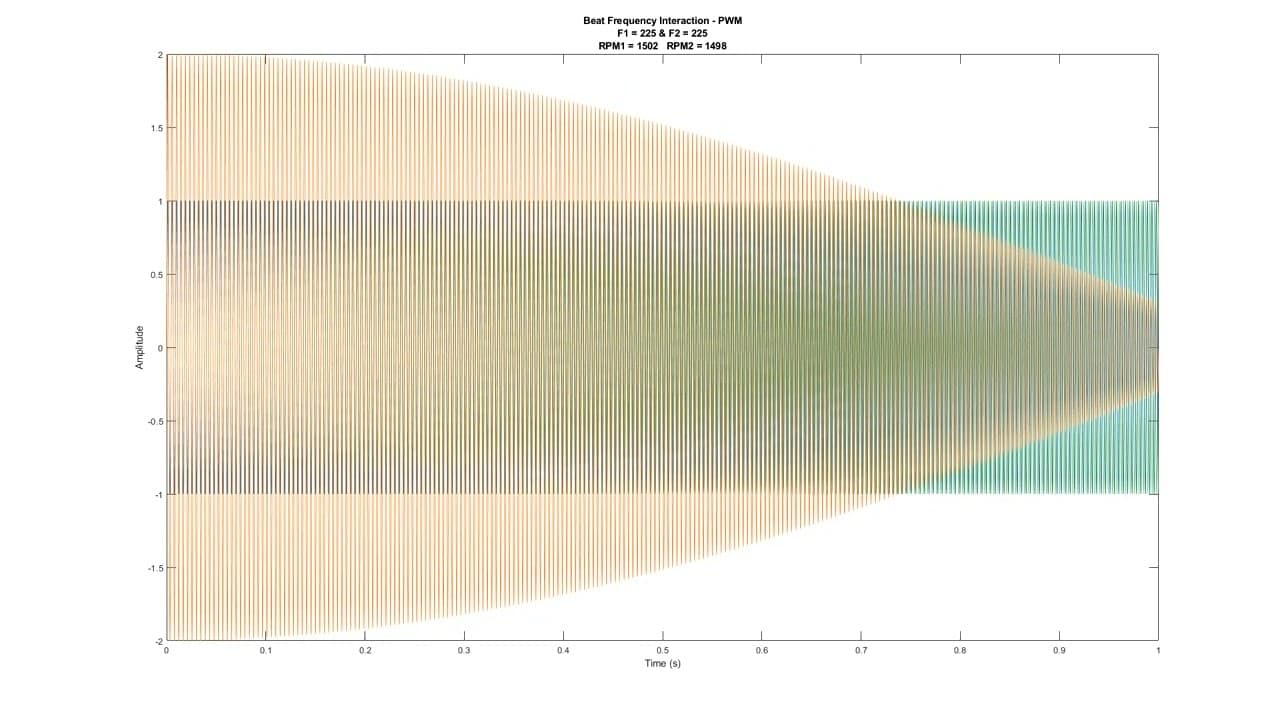

Thanks to the high-accuracy speed control of the NE-FD6 driver IC and its SupraTorque™ feature that enables the NF-A12x25 G2 and NF-A14x25(r) G2 to keep their nominal set speed even when working against significant flow resistance, sample-to-sample speed variation between two fans can typically be kept below 10rpm. Let’s therefore assume that two NF-A14x25(r) G2 fans vary in speed by 10rpm, one runs at 1505rpm and the other at 1495rpm. Knowing that that the NF-A14x25(r) G2 utilises a nine-blade impeller design, we can calculate the fans’ BPFs to be 225.75 Hz (1505*9/60) and 224.25 Hz (1495*9/60). With the BPFs calculated, a simplified version of the beat phenomenon can be visualised as two sine waves with the corresponding BPF of each fan:

Due to the two signals differing so little in frequency, they are almost, but not quite in phase with each other, so they produce a slow beat frequency of 1.5 Hz:

The following video illustrates this BPF interaction of two NF-A14x25 G2 PWM fans, one at 1505rpm (225.75 Hz) and one at 1495rpm (224.25 Hz) and the distinct periodic humming this creates:

When listening to the video, it is important to note that it is not representative of what the fans actually sound like as it is not based on real recordings. Instead, for clarity’s sake, it uses artificially generated sine waves to represent the fans’ BPFs, so the beat frequency is much more prominent than it would be with the fans’ real noise profile. As fans possess a complex acoustic profile that is spread out across a wide frequency spectrum, beat frequency interactions are much more difficult to perceive than with isolated sine tones. Real world recording examples can be found further below.

As explained, beat frequencies become faster the bigger the difference in frequency between the original signals is and the faster the beat frequency, the more difficult it becomes to perceive for human hearing, which is why faster beat frequencies are generally perceived as less distracting.

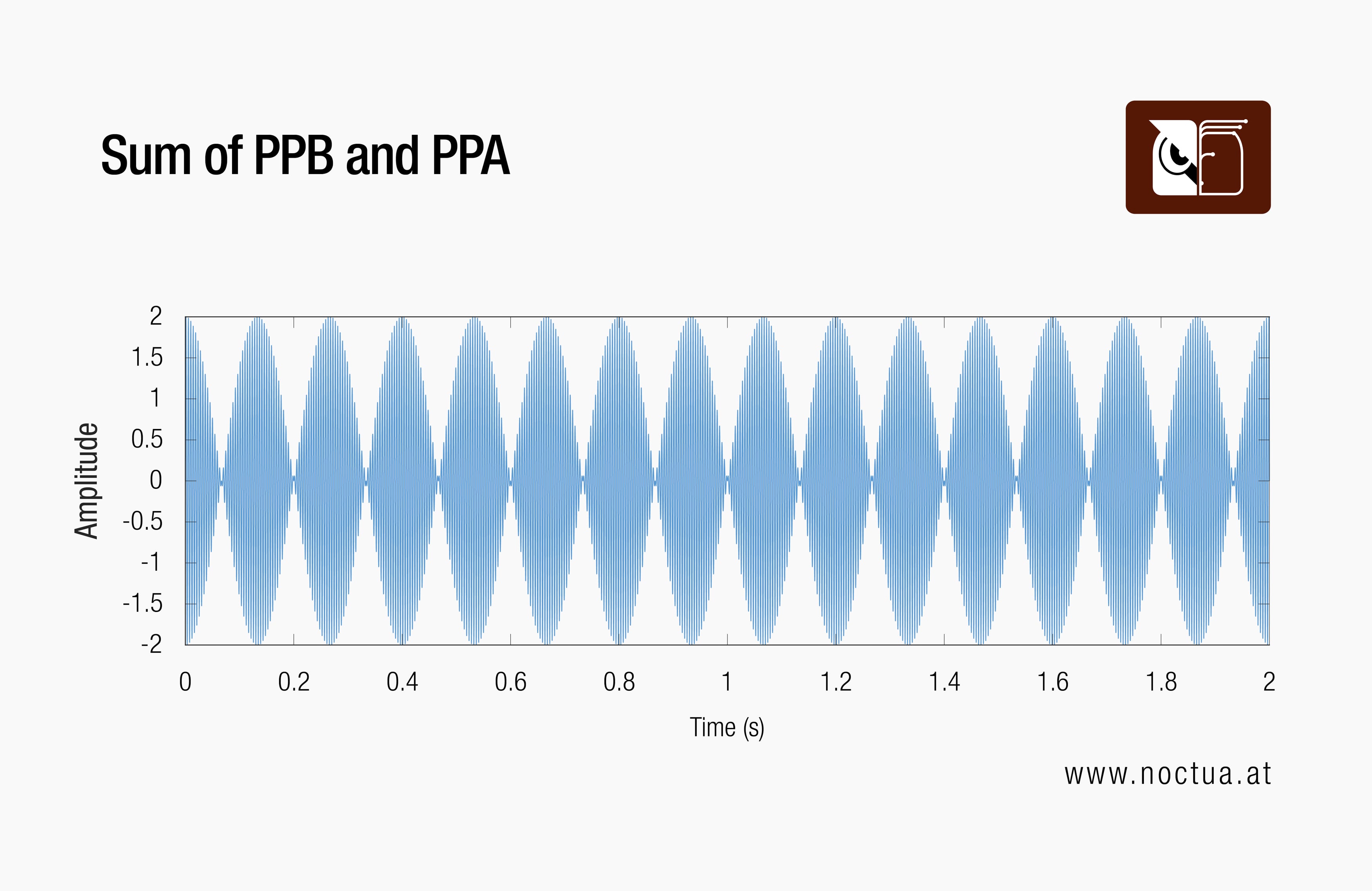

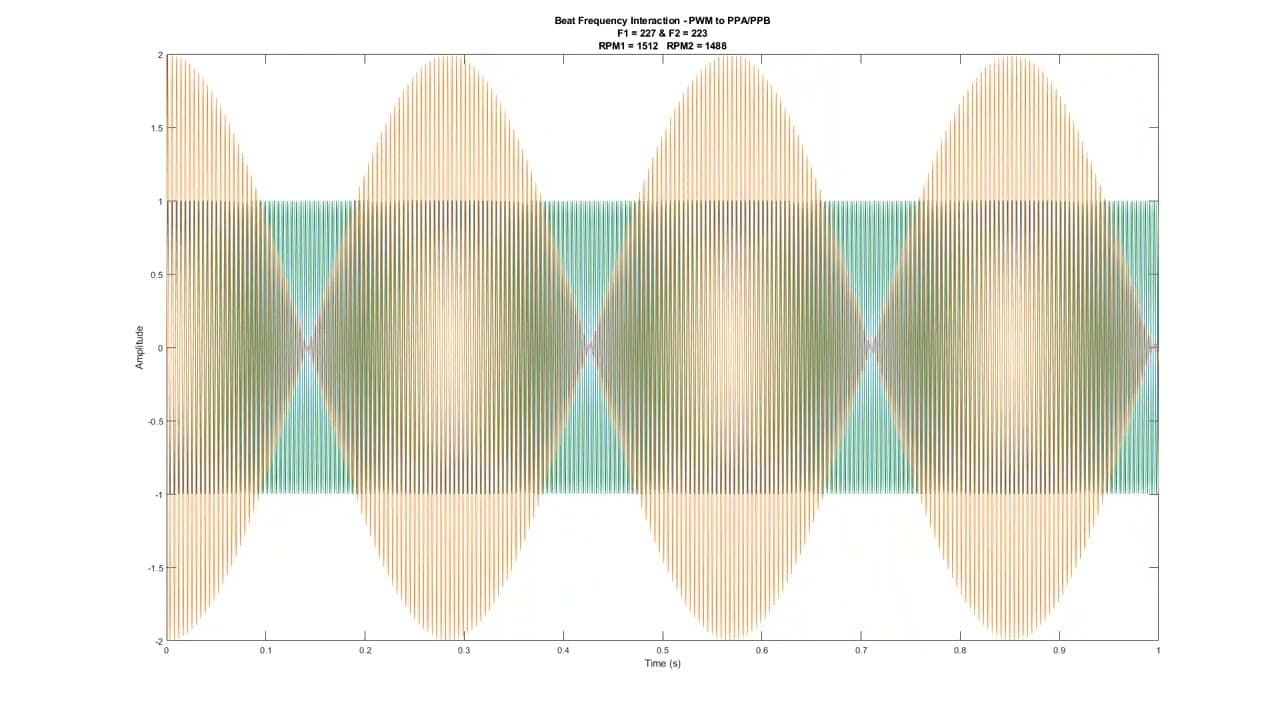

This is where the speed offset of the PPA and PPB models used on the NH-D15 G2 as well as in the 140mm Sx2-PP dual fan sets steps in: With one fan running ~25rpm faster and the other fan running ~25rpm slower, their acoustic profiles are shifted far enough for the beat frequency to become much faster (7.5 Hz instead of 1.5 Hz):

The total ~50rpm speed offset between the PPA and PPB 140mm NF-A14x25(r) G2 fans will make the beat frequency fast enough to prevent periodic humming or intermittent vibrations so that it will no longer be noticeable for most listeners. At the same time, the speed reduction on the PPA fan is small enough to avoid a measurable impact on thermal performance. Similarly, the ~100rpm speed offset between the PPA and PPB 120mm NF-A12x25 G2 fans will yield identical acoustic results, while the slight speed reduction on the PPA fan remains negligible, ensuring no measurable effect on thermal performance.

Since the perception of beat frequencies and, in particular, the point at which they become too fast to be noticeable, depend on individual psychoacoustic preferences, customers who want to do additional acoustic fine-tuning are invited to try further increasing the offset by slowing down the PPA fan. In the case of the 140mm NF-A14x25(r) G2 fans, reducing the speed of the PPA fan by another 50-70rpm to 1405-1425rpm should be sufficient to make the beat frequency inaudible even for listeners who are more sensitive to faster beat frequencies. The effect of this additionally increased speed offset is illustrated in the following video:

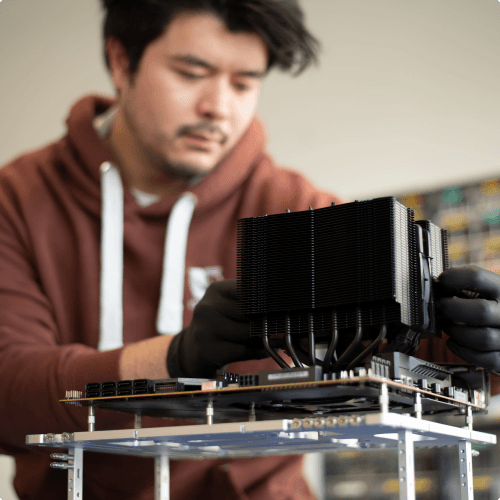

Once again, it is important to note that these videos have been created using sine wave representations of the fans’ BPFs in order to clarify the acoustical background phenomena. Real world fan noise does not only consist of a single BPF, but possesses a much more complex spectral profile, which means that beat frequency interactions of the BPFs are much less noticeable. The following recordings of two NF-A14x25r G2 fans on a NH-U14S heatsink provide a better understanding of how the different configurations will sound in a real-world setting:

No speed offset:

50rpm speed offset (PPA/PPB):

125rpm speed offset (PPA fan speed reduced to 1400rpm:

275rpm speed offset (PPA fan speed reduced to 1250rpm using Low-Noise Adaptor):

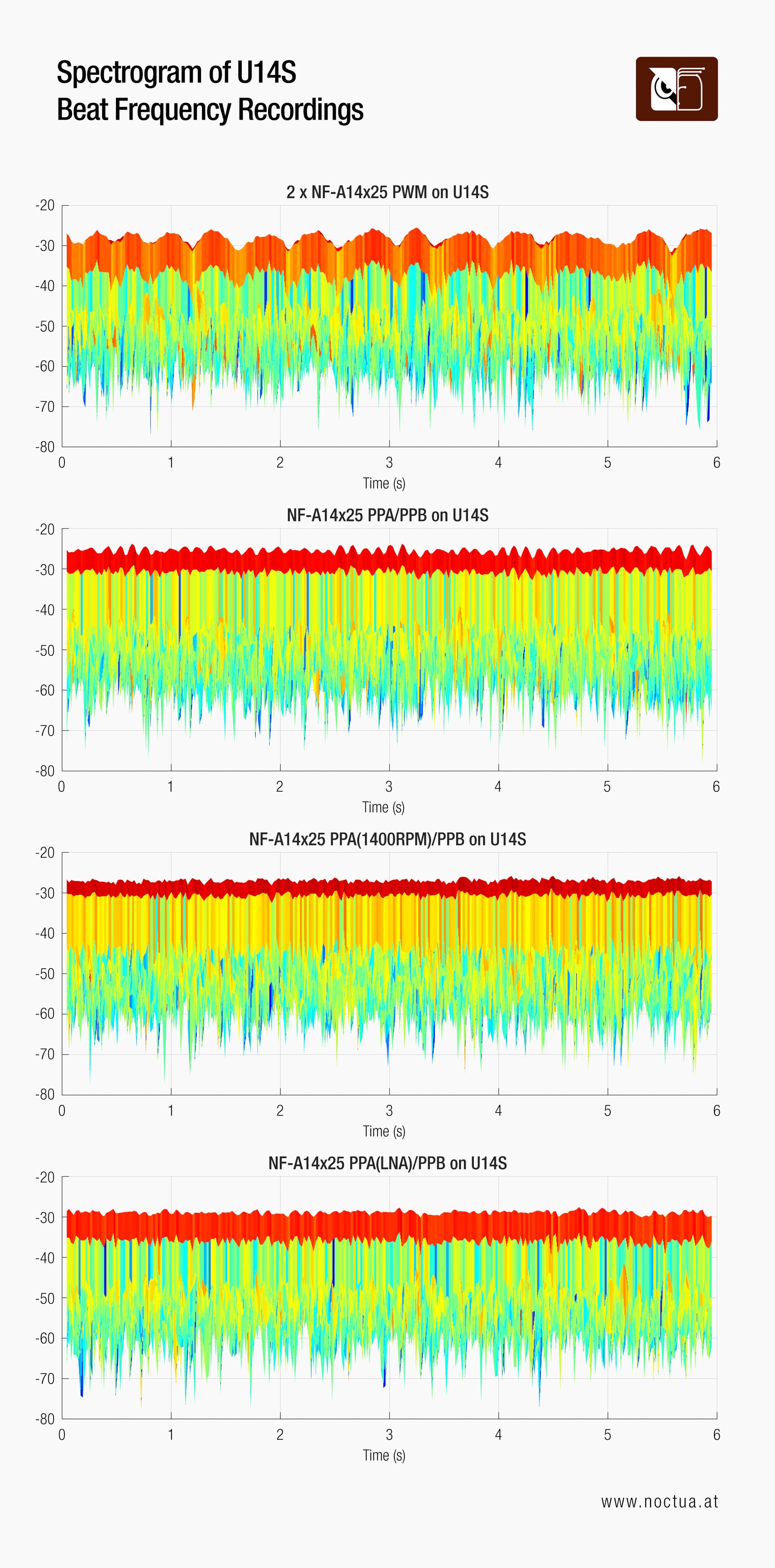

The following spectrograms visualise the acoustic data contained in the above recordings. As such, they demonstrate that there is a distinct slow beat frequency with large variations in amplitude (high peaks alternating with deep notches) when using fans without dedicated speed offset. As can be seen in the subsequent spectrograms, this variation in amplitude is reduced by increasing the RPM difference between the two fans. At the same time, it can be seen how the beat frequency and its amplitude modulation gradually become faster as the rate of the peak and notch variation increases:

As the spectrograms show, the 50rpm default offset provided by the PPA/PPB fans used on the NH-D15 G2 and in the 140mm Sx2-PP fan set is sufficient for reducing the amplitude variations of the beat frequency significantly and makes them fast enough so that they are perceived as a tone of high roughness that should not be distracting for most users. At the same time, the offset is small enough to avoid a measurable impact on thermal performance. For customers who are more sensitive to faster beat frequencies, the offset can be further reduced by slowing down the PPA fan via PWM control or using the supplied Low-Noise Adaptor. This will further reduce the amplitude variations and further increase their rate so that they are no longer perceptible.

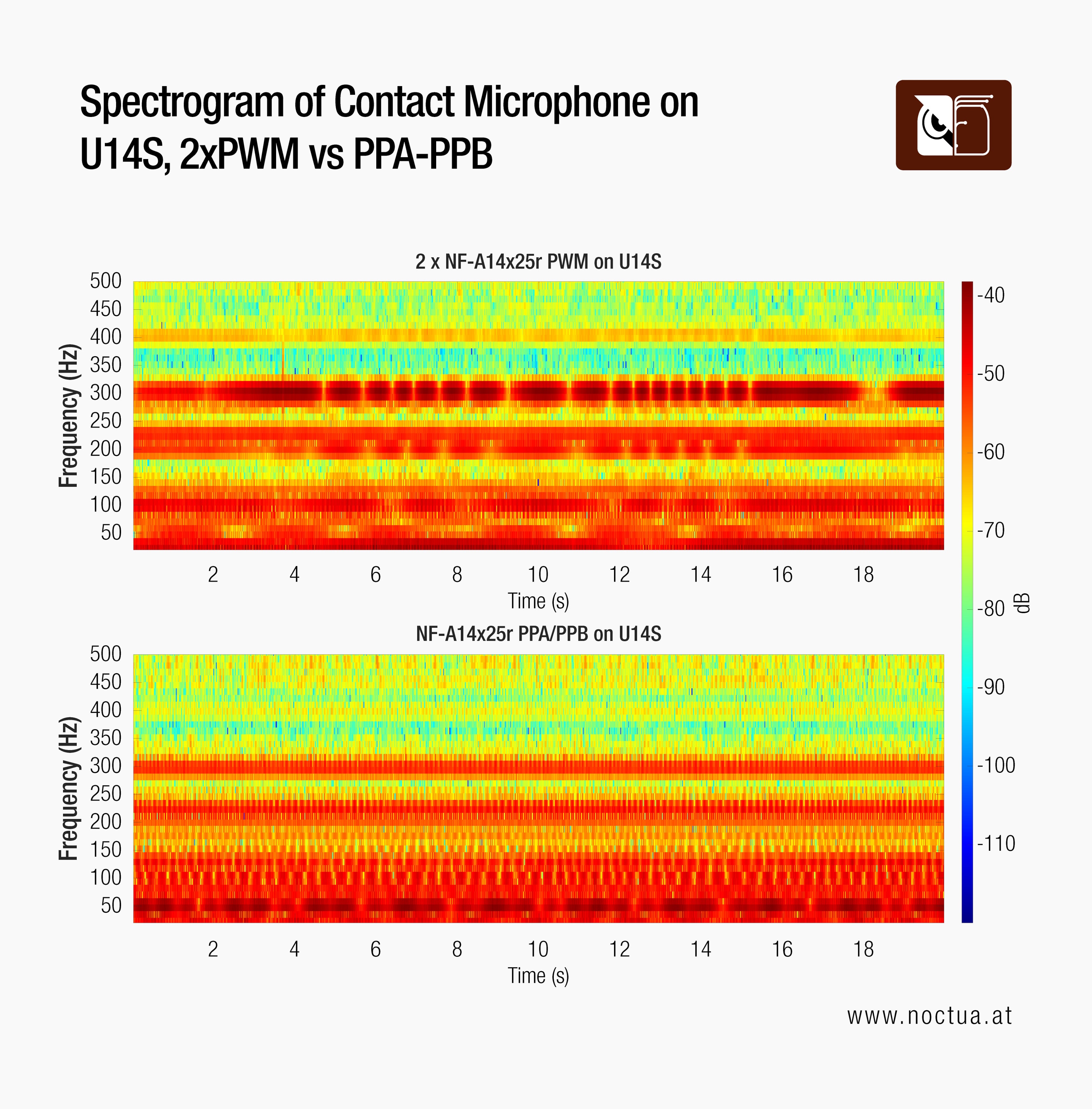

In addition to these acoustic considerations, it should be taken into account that beat frequencies also bear the risk of causing intermittent vibrations, which can be measured using contact microphones. The following spectrograms show measurements that have been conducted using a contact microphone placed on at the base of an NH-U14S heatsink:

As can be seen from the spectrograms, the configuration without offset can produce measurable intermittent vibrations in the ~300 Hz range. By contrast, the strong pressure fluctuations in the ~300 Hz range are absent with the speed offset PPA/PPB configuration due to the much faster beat frequency, so there is no risk of resonant vibrations building up. Whether or not this tendency for intermittent vibrations is noticeable in real world usage will vary from system to system. For example, some PC cases will be more prone to pick up vibrations than others and vibrations will transfer differently through the motherboard depending on the CPU cooler mounting hardware or which other components such as GPUs are installed. Even though there may be no actual vibration issues in many builds, the speed offset definitely puts customers on the safe side in so far as it effectively eliminates the risk that such vibration phenomena might occur.

Related articles

Want to know more on this topic? Explore relevant articles and resources.

Superior quiet cooling: ASUS RTX 5080 Noctua Edition performance analysis

Featuring three NF-A12x25 G2 fans and a custom-engineered heatsink, the ASUS RTX 5080 Noctua Edition GPU sets a new benchmark for near-silent performance.

How to make the Framework Desktop run even quieter

Discover how custom Noctua mods and 3D-printed parts can make the Framework Desktop PC cooler, quieter, and even more impressive.

NA-IS1 performance guidelines

Inlet spacers can reduce turbulence in suction applications, improving both acoustics and performance. But how do these improvements vary across fan models and applications?

What makes the Seasonic PRIME TX-1600 Noctua Edition so quiet?

The Noctua Edition is around 8-10dB(A) quieter than the regular model across the entire fan speed range, but what is the key to this stark difference?

.jpg&w=3840&q=85)