In PC environments, the options for fan placement are usually predetermined by the application, e.g. a chassis having a certain amount of fan placements, a heatsink fitting one or two fans or a radiator fitting a certain amount of fans in push, pull or push/pull. By contrast, when designing custom ventilation setups outside of the realm of PCs, there can be plenty of options regarding fan configuration and placement. Many custom-designed setups require more ventilation than a single fan can deliver, so this can prompt the question whether two (or pairs of two) fans should be placed in series or parallel operation. In general, combining axial fans in series does not increase the airflow but increases the air pressure. On the other hand, running fans in parallel does not increase the static pressure but increases the airflow. This article sums up the theoretical backgrounds and provides some general guidelines for designing series and parallel operation setups.

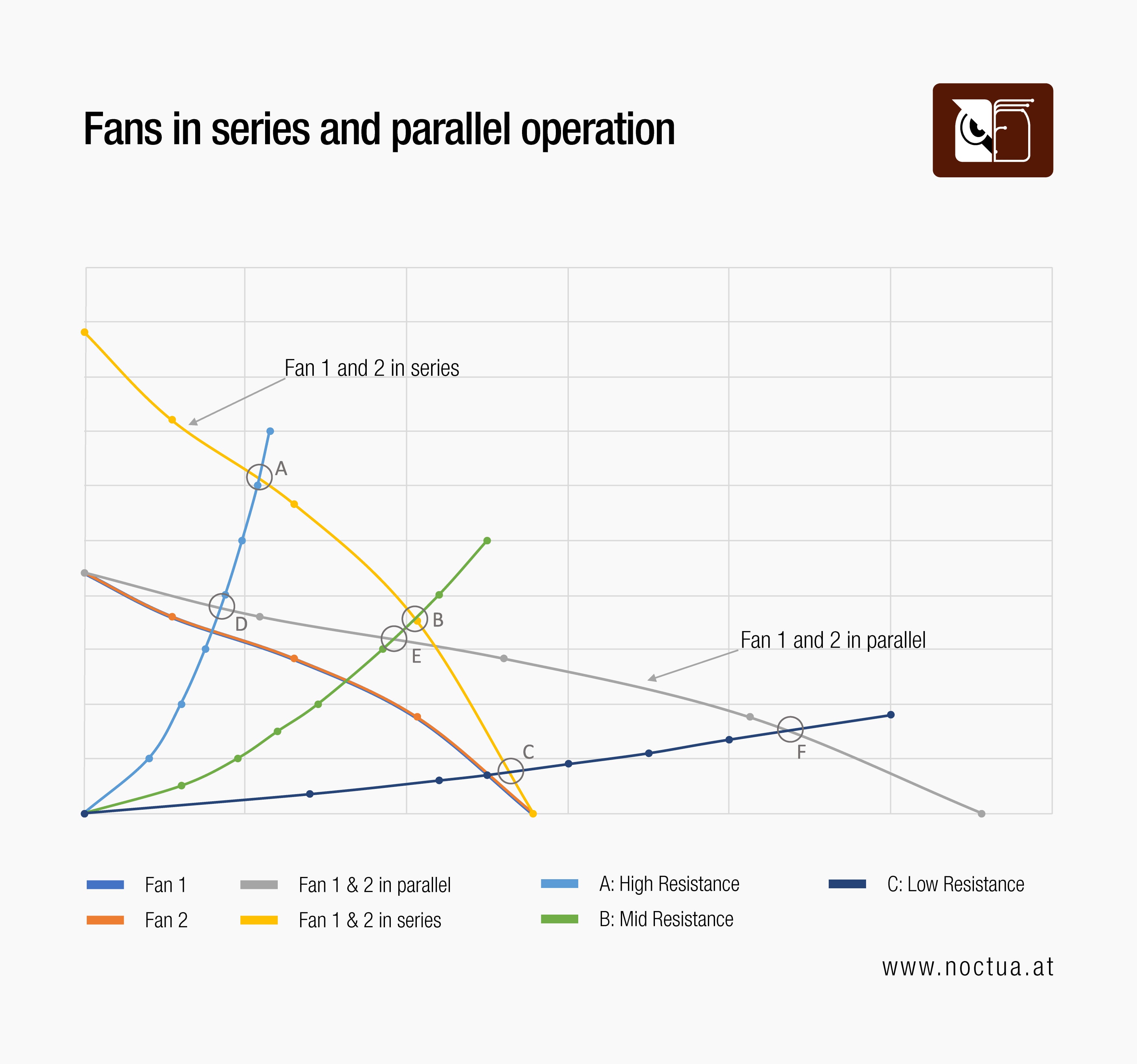

When an increased air volume or pressure becomes necessary for an application, multiple fans can be used instead of replacing a single fan with a larger capacity fan. In Figure 1, Fan 1 and Fan 2 are the same model. Installing them in series or parallel gives the combined theoretical curves shown. Depending on whether the system has high or low airflow resistance, series or parallel operation setups can be more beneficial. In mid-resistance setups, series or parallel operation setups may yield similar results. An example of a high resistance system could be a system with high FPI radiators or dense filters that significantly obstruct the airflow. Low resistance systems on the other hand tend to have more loosely spaced components and a relatively open outlet side, making it easier for volume of airflow to pass.

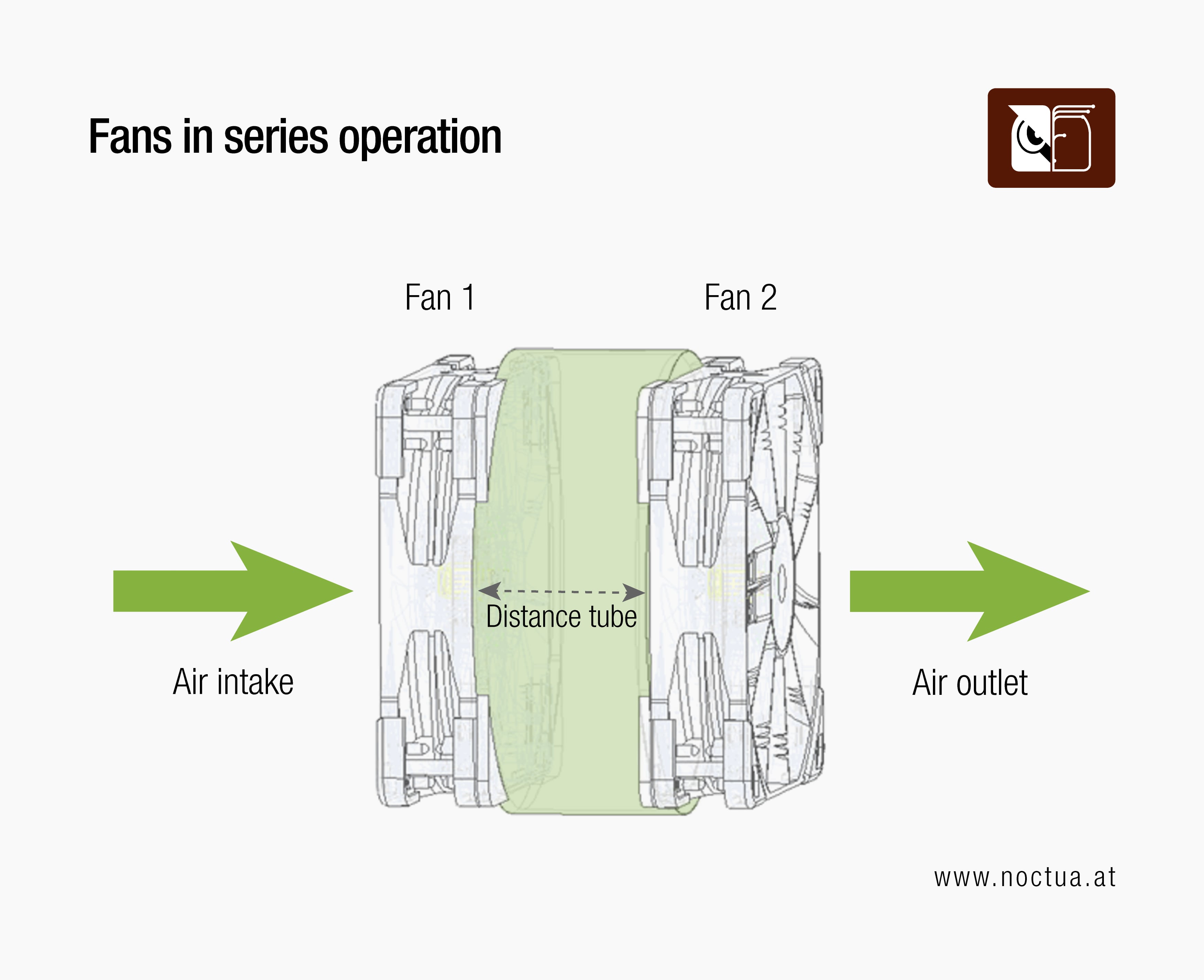

Fans in series operation

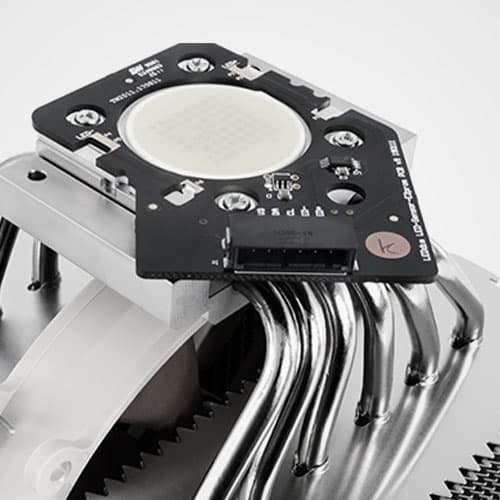

When two fans are installed after each other in a row (see Figure 2.) and the same air passes through both of them, they are acting in series. The first fan in a series operation setup supplies air pressure into the inlet of the second fan. If the fans are mounted in series, they are working in tandem to produce a greater pressure difference than one fan. Figure 1 shows that when the series operational fans are in so called stall (maximum pressure), the static pressure is theoretically double that of one individual fan. However, the total amount of airflow at zero pressure will not increase compared to using a single fan.

Looking at Figure 1, the operational point for Fan 1 and 2 in series operation in a high resistance system is shown at point A. For a mid-resistance system, the operational point is represented in point B, and for a low resistance system see point C. As can be seen from the curves, the series setup gives the biggest benefit in higher resistance applications, but little benefits versus a single fan configuration in low resistance configurations.

Considerations when designing systems with fans in series operation:

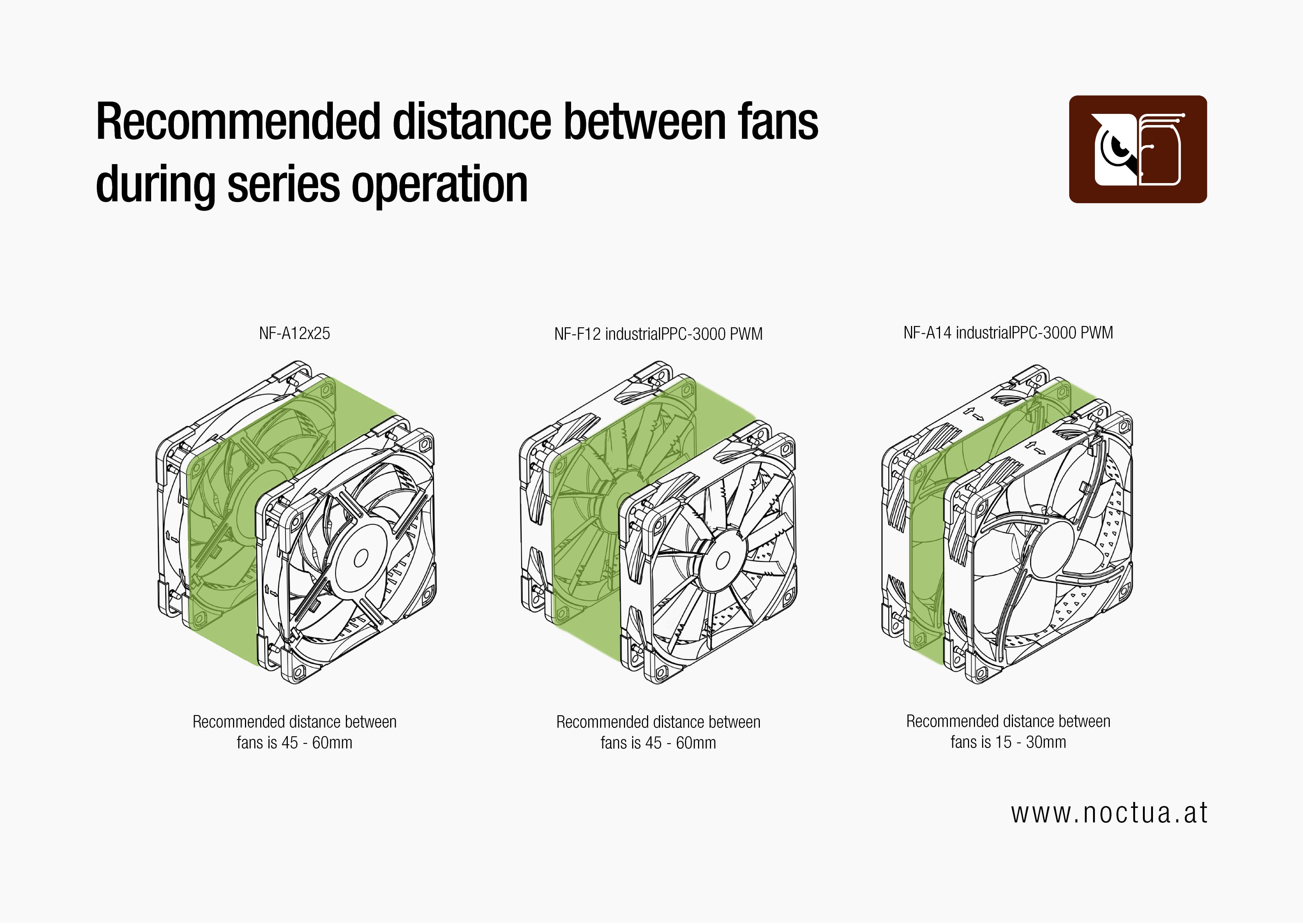

When running fans in series operation they should not be placed directly towards each other as this can result in reduced aero-acoustical performance due to turbulence, decreasing the benefit of the series operation mode.

The recommended distance between the fans for NF-A12x25, NF-F12 industrialPPC-3000 PWM and NF-A14 industrialPPC-3000 PWM in series operation is shown below. Note that these recommendations refer to setups where airflow between the fans is not obstructed by heatsinks, filters or radiators. If radiators or other objects are placed between the two fans in so called push/pull setups, these objects tend to straighten the airflow, so usually, lower distances can be used.

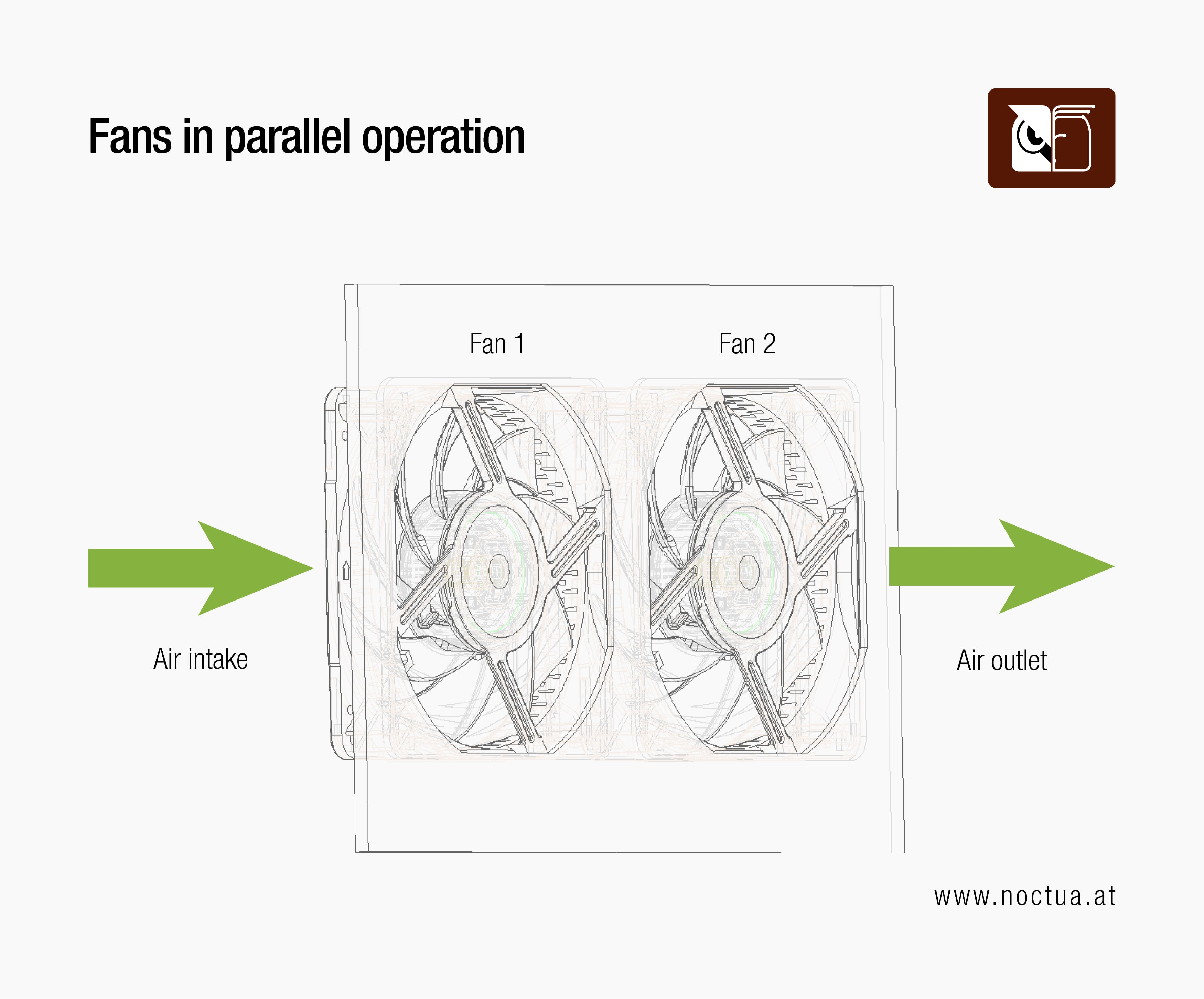

Fans in parallel operation

When two fans are installed side by side, blowing into the same direction as in Figure 4, they are operating in parallel.

When fans are operating in parallel, the combined performance shows an increased volume of airflow. In theory, the total airflow volume will be doubled compared to a single fan. By contrast, total static pressure at zero airflow (stall) will not increase compared to a single fan. The actual performance gains will depend on the airflow resistance of the system, with parallel operation setups generally providing better results in low resistance systems.

Looking at Figure 1 the operational point for Fan 1 and 2 in parallel operation in a high resistance system is shown at point D. For a mid-resistance system, the operational point is represented at point E, and for a low resistance system see point F. As can be seen, parallel operation setups tend to yield good results at low to mid resistance, but in systems with mid to high resistance, series operation setups are preferable.

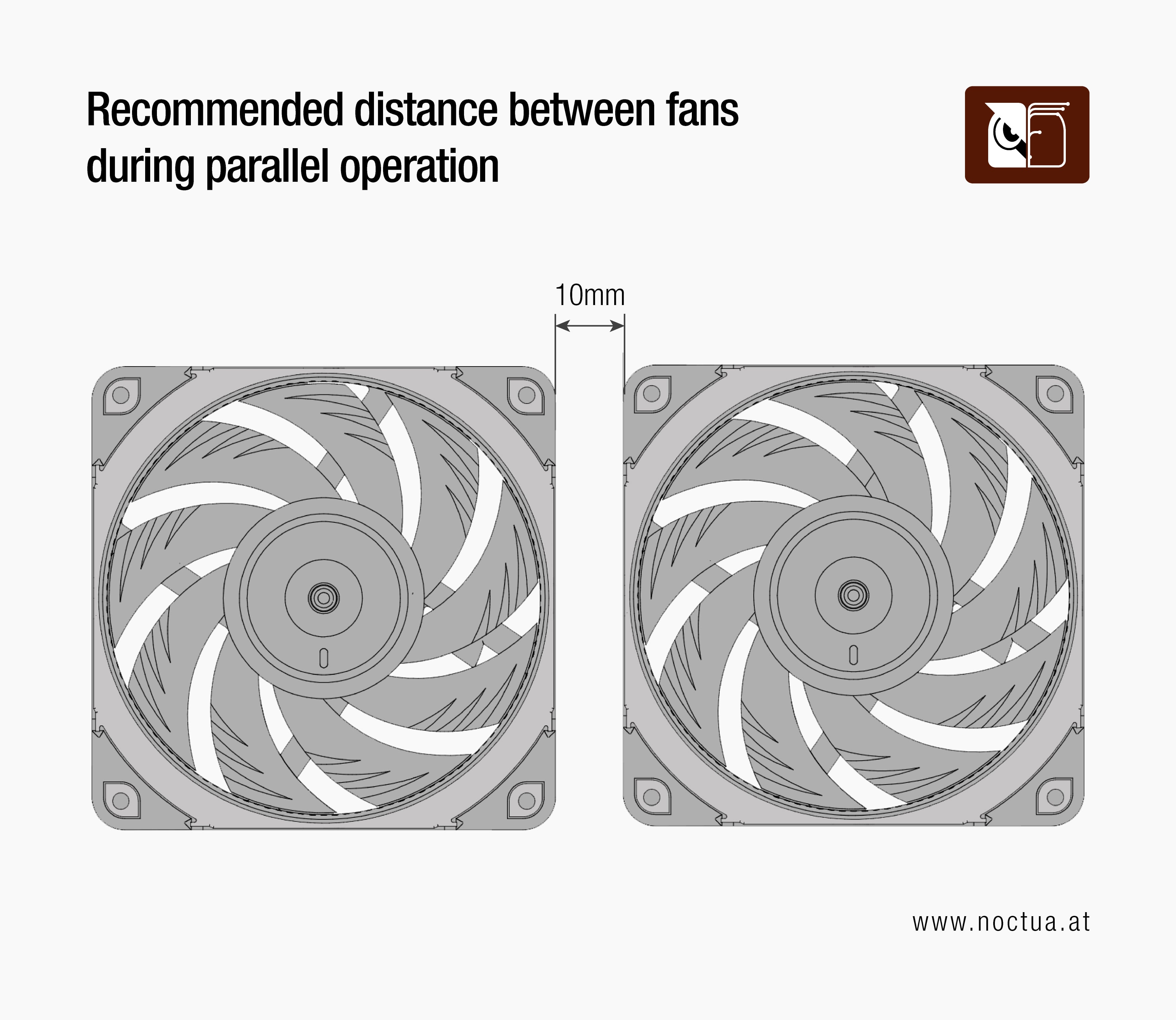

Considerations when designing systems with fans in parallel operation:

When running fans in parallel operation, placing the fans too close to each other may result in slightly increased turbulence noise. If space allows, a distance between the fans of about 10 mm is recommended, as shown in Figure 5.

Related articles

Want to know more on this topic? Explore relevant articles and resources.

NF-A12x25: performance comparison to NF-F12 and NF-S12A

See how the NF-A12x25 stacks up against the NF-F12 and NF-S12A in airflow, pressure, and real-world performance.

NF-A12x25 G2: further refined performance in all applications

The NF-A12x25 G2 represents another step up in performance, surpassing its renowned predecessor in all typical use cases.

NA-IS1 performance guidelines

Inlet spacers can reduce turbulence in suction applications, improving both acoustics and performance. But how do these improvements vary across fan models and applications?

NF-A14x25(r) G2 performance: improvements for heatsinks, radiators and cases

The next-gen NF-A14x25 G2 takes cooling performance to the next level, but what specific improvements can you expect to see compared to its predecessor?