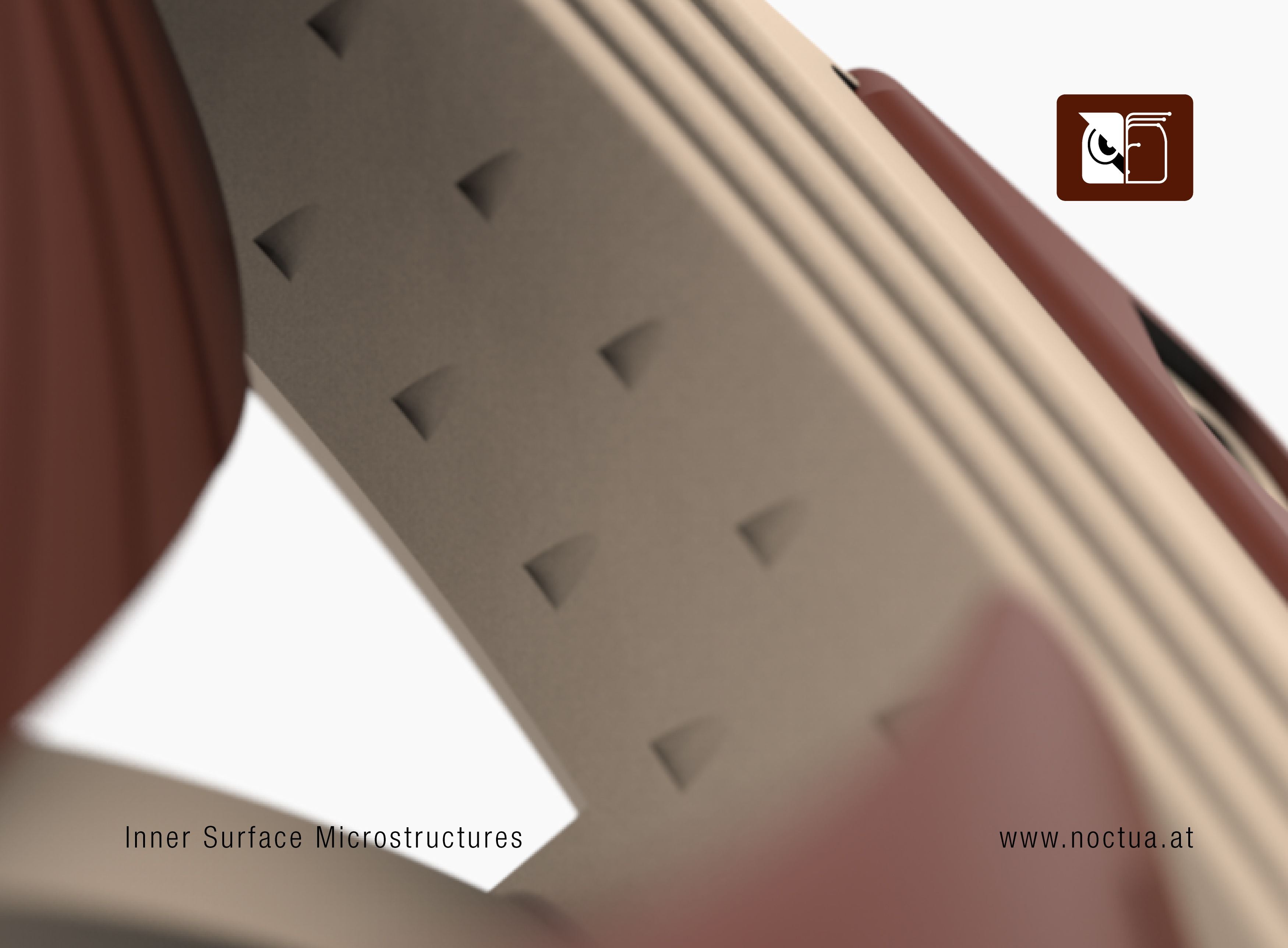

Inner Surface Microstructures

Inner Surface Microstructures

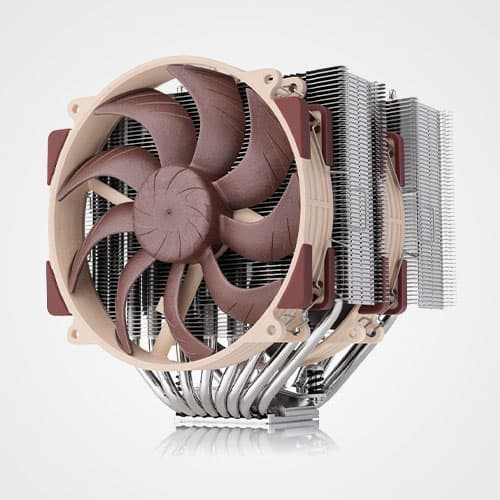

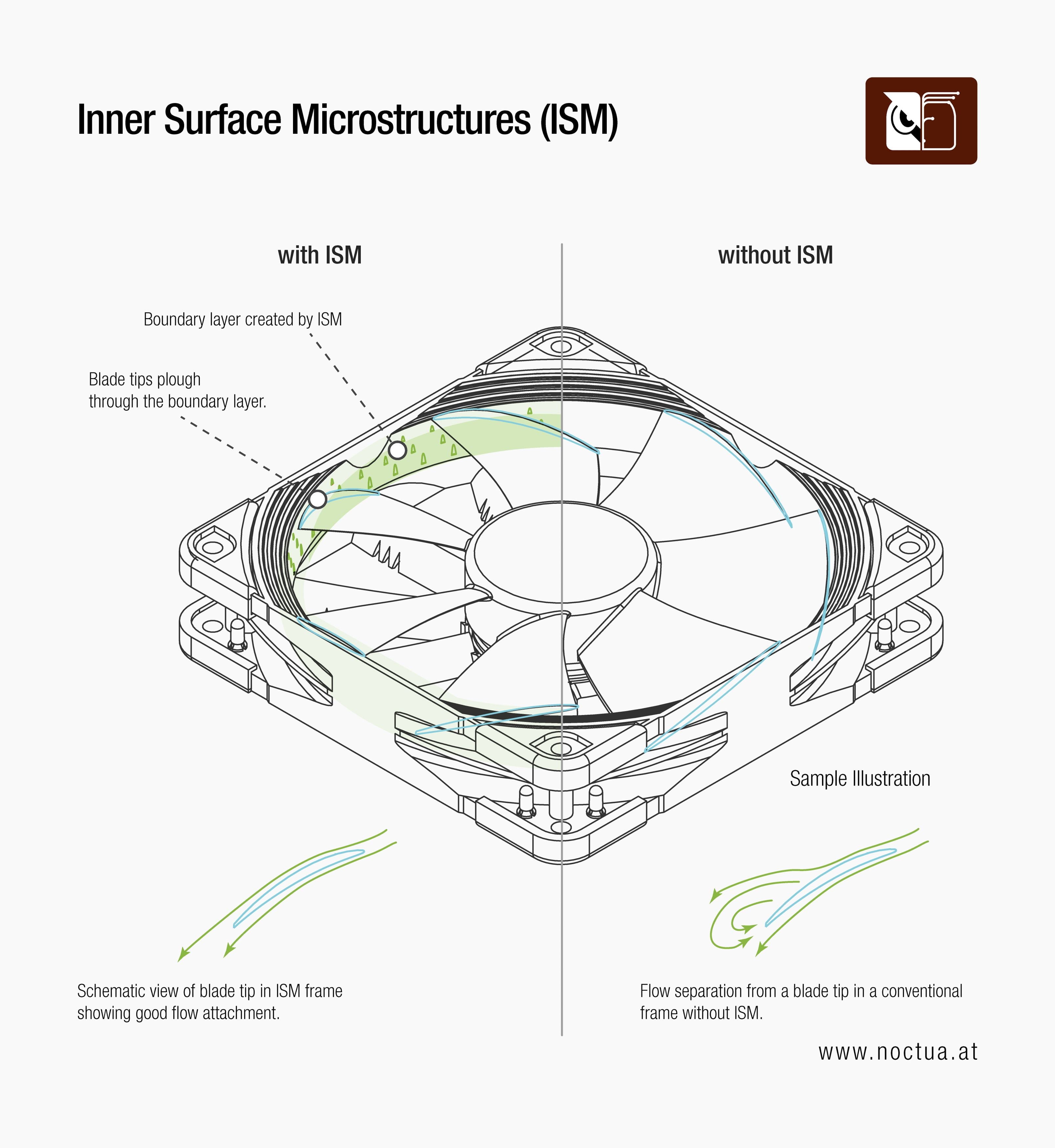

Inner Surface Microstructures are an advanced aerodynamic design measure first introduced with Noctua’s NF-F12 fan. Miniature dents at the inside of the fan frame create a turbulent boundary layer when the fan blades pass by. With the tips of the fan blades ploughing through this boundary layer, flow separation from the suction side of the blades is significantly reduced.

As suction side flow separation is a major source of axial fan blade passing noise and leads to considerable losses in airflow and pressure efficiency, the use of Inner Surface Microstructures allows for lower noise emission and better performance at the same time. Reducing undesired turbulences caused by suction side flow separation, Inner Surface Microstructures help Noctua’s latest fans to keep pushing the boundaries in performance to noise efficiency.

Related articles

Want to know more on this topic? Explore relevant articles and resources.

AAO Frame

Noctua’s AAO frames contain anti-vibration pads, a Stepped Inlet Design, and Inner Surface Microstructures for improved performance and noise efficiency.

Focused Flow™ Frame

With 11 guide vanes, the Focused Flow™ frame focuses airflow for pressure-heavy tasks like heatsinks and radiators.

Metal bearing shell

Many of Noctua's models sport a CNC milled bearing shell made entirely from brass.

Stepped Inlet Design

Noctua’s Stepped Inlet Design helps improve airflow efficiency and reduce tonal intake noise, resulting in smoother, quieter fan performance.