NH-D15 G2 versions: heatsink contact quality optimisation explained

Taking platform-specific optimisation to a new level, the NH-D15 G2 is available in a regular, medium base convexity standard version as well as specialised Low Base Convexity (LBC) and High Base Convexity (HBC) variants. The background of this is that not all CPUs are created equal. In fact, today’s desktop processors differ significantly with regard to the flatness of their heatspreaders as well as their die configuration and hotspot location.

Surface flatness and hotspot location

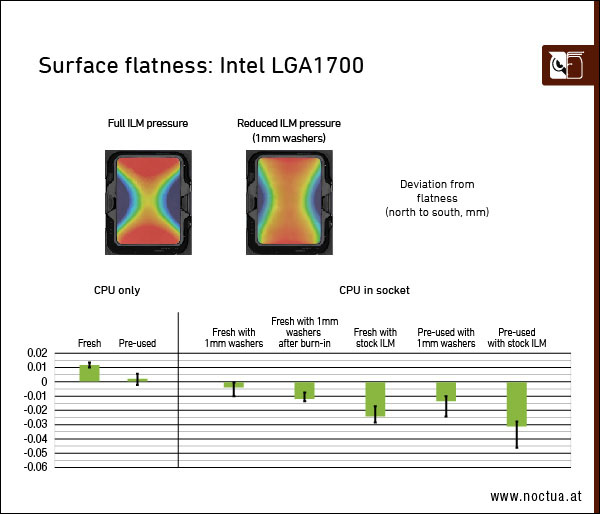

Intel LGA1700: deformations due to ILM pressure

Intel LGA1700 processors are slightly convex factory new but become highly concave once the socket’s ILM (internal loading mechanism) is closed to press the CPU into the socket. This deformation can be reduced by putting 1mm washers underneath the ILM to reduce ILM pressure (the so called “washer mod”) or by using custom ILM replacements that apply less pressure (“contact frames” or “bending reduction frames”). However, when CPUs have been used with full ILM pressure for longer periods of time, the deformation can become partly plastic (i.e. the CPUs are permanently deformed and don’t go back to their original shape when removed from the socket). In these cases, reducing pressure by using washers or custom ILMs will only show limited improvements. Whether or not a CPU has become permanently deformed will depend on various factors such as tolerances in ILM pressure, differences in CPU and socket height, thermal cycling, heatsink mounting pressure and surface flatness of the heatsink(s) used.

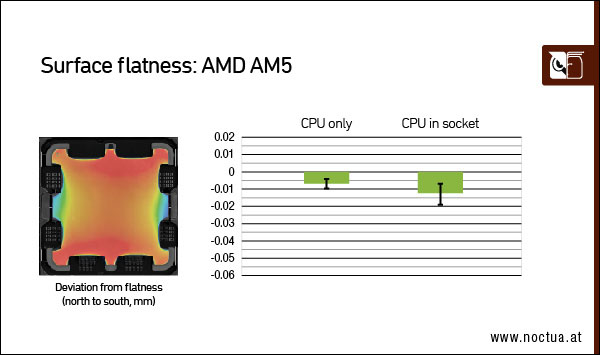

AMD AM5: flatness and off-centre hotspot

AMD AM5 CPUs, by contrast, stay comparably flat. While the numerical north-to-south deformation values are similar to Intel LGA1700 CPUs that are used with 1mm washers to reduce ILM pressure, the deformation is mostly limited to the tabs where the Socket Actuation Mechanism (SAM) applies pressure. The central area that is critical for heatsink contact quality stays quite flat:

At the same time, it must be taken into account that AMD AM5 CPUs have their CCD(s) shifted towards the south side of the socket, so whereas LGA1700 processors require optimal contact in the centre, contact in the area above the CCDs is crucial for AMD CPUs.

LGA1851: ILM types and hotspot location

LGA1851 processors generally show less deformation than LGA1700 ones. Most LGA1851 motherboards (all Z890 and B860 models as well as most H810 boards) use the so-called RL-ILM. “RL” stands for “reduced load” and LGA1851 sockets using this ILM type exert a similar, reduced amount of pressure onto the CPU as LGA1700 sockets that have been modified with 1mm washers. As a result, the IHS deformation of LGA1851 CPUs used in RL-ILM sockets is similar to fresh LGA1700 CPUs that are used with 1mm washers. Even with the other LGA1851 ILM type, the so called “default” ILM that is only used on a few H810 motherboards at this stage, LGA1851 processors tend to deform slightly less than LGA1700 ones that are used with full ILM pressure.

Unlike LGA1700 CPUs, 20- and 24-core LGA1851 CPUs such as the Core Ultra 9 285K or Core Ultra 7 265K have their hotspot location shifted towards the north-east side of the IHS. 14-core models like the Core Ultra 5 245K have a relatively centric hotspot.

.

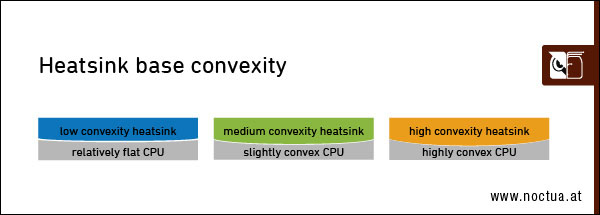

Surface fitment versus contact quality

As a basic rule of thumb, the shapes of the contact surfaces of the heatsink and the processor should fit each other as precisely as possible in order to achieve good contact. Consequently, a relatively flat heatsink base will show the best fitting on relatively flat CPUs (such as AMD AM5 and AM4 or Intel LGA2066) whereas a highly convex heatsink base is required to achieve a good fit on highly concave CPUs (such as Intel LGA1700 with full ILM pressure). Slightly convex CPUs (such as Intel LGA1851 CPUs with RL-ILM or LGA1700 CPUs with reduced ILM pressure) will show best fitting with medium convexity heatsink bases.

However, contact quality is not only about achieving the largest possible area of contact, but also about optimal pressure distribution: In order to achieve optimal contact quality and thermal transfer from the processor die(s) to the heatsink, the key point is to have optimal pressure right above the processor’s hotspot. In case of AMD AM5 CPUs that have their hotspot caused by the CCD(s) located at the south side of the socket, this means that it’s more important to have good pressure in this region rather than applying even pressure over the entire heatspreader. This is why a medium convexity heatsink that is centred over this hotspot with an offset mounting will perform just as good as or even slightly better than a cooler with a flatter base.

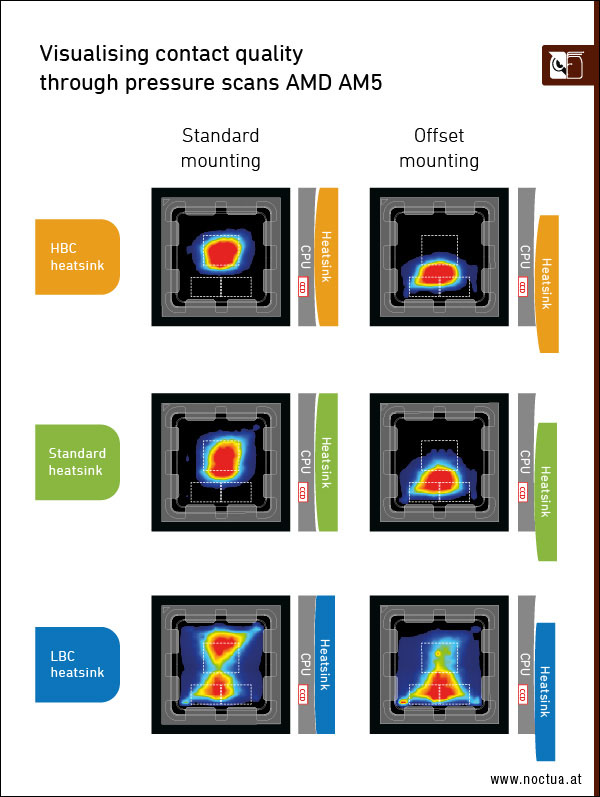

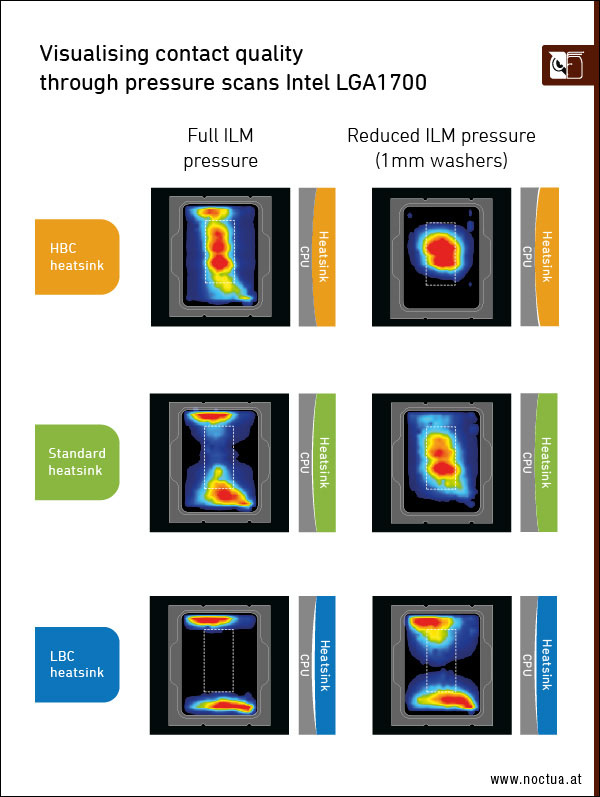

Visualising contact quality through pressure scans

We use high-precision pressure scanners to analyse heatsink contact quality. The following scans illustrate the contact quality of heatsinks with low, medium and high base convexity on AMD AM5 with and without offset mounting as well as on Intel LGA1700 with full and reduced ILM pressure (1mm washers underneath the ILM):

AMD AM5 contact patterns

Comparing the pressure scans on AM5, it can be seen that the low base convexity heatsink provides the largest overall contact area, covering both the IOD and the CCD(s) with good pressure. However, the medium convexity heatsink paired with the offset mounting provides even better pressure concentration right above the CCD(s), which enables it to perform on par with or even slightly better than the low convexity cooler that provides a larger but more even pressure distribution. In comparison, the pressure pattern of the high base convexity heatsink is a bit too concentrated, so even when used with the offset mounting, it will slightly lag behind the low and medium convexity versions. While Ryzen 3000 and 5000 series AM4 CPUs have a similar off-centre CCD location, they tend to benefit less from offset mountings and show better results with low convexity heatsinks.

Intel LGA1700 contact patterns

When looking at the Intel LGA1700 pressure maps, the high base convexity heatsink provides the best possible contact quality if the CPU is used with full ILM pressure, combining broad overall coverage with excellent pressure concentration over the die. Once ILM pressure is reduced by using 1mm washers, the medium base convexity standard cooler achieves the best contact pattern, showing good concentration in the centre and broad overall coverage similar to the HBC version with full ILM pressure. By contrast, the HBC version’s contact patch is slightly too concentrated with reduced ILM pressure in the scans shown above. It must be noted, however, that this may vary depending on how much permanent deformation an LGA1700 CPU has seen from long term use: With strongly deformed units, the HBC version may provide the best possible contact even with reduced ILM pressure. By contrast, the low base convexity LBC heatsink generally shows poor contact on LGA1700: Pressure is applied only at the north and south side edge of the heatspreader and the critical centre section is completely uncovered, leaving it to the thermal paste to fill the gap. While the situation can be improved somewhat by adding 1mm washers to reduce ILM pressure, the contact quality of low base convexity heatsinks will always remain suboptimal on LGA1700.

Intel LGA1851 contact patterns

Intel LGA1851 CPUs that are used with RL-ILM sockets show broadly the same contact patterns as fresh LGA1700 CPUs that are used with reduced ILM pressure (1mm washer mod), so the best contact quality is achieved by medium base convexity heatsinks. HBC heatsinks show a slightly too centre-focused contact pattern and LBC heatsinks lack contact in the centre.

LGA1851 processors that are used with default ILM motherboards fall somewhere in between LGA1700 processors with full ILM pressure and LGA1700 processors with 1mm washers.

Versions and versatility: Why we have changed our approach with NH-D15 G2

At Noctua, we have always been convinced that it is preferable to have heatsinks that work equally well across different platforms, especially because this enables customers to keep using their heatsinks across multiple platform generations with excellent results. Therefore, all our multi-socket coolers come with a medium convexity base and an offset mounting option for AMD AM5. This way, they provide perfect contact on slightly concave processors such as LGA1851 (RL-ILM) or LGA1700 CPUs with reduced ILM pressure (“washer mod” or “contact frames”), optimal results on AMD AM5 when using the offset mounting option and solid performance on LGA1700 CPUs that are used with full ILM pressure or have become permanently deformed from ILM pressure. This approach enables us to offer heatsinks that are highly versatile and will consistently provide excellent results even when switching between different CPU types.

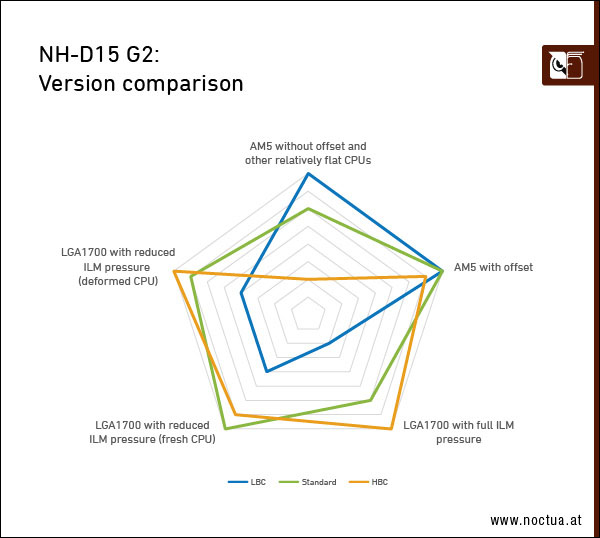

When developing the NH-D15 G2, however, we ultimately decided to take platform specific optimisation to a new level: Since we put so much time and effort into squeezing out every last drop of performance and left no stone unturned to make this cooler push the boundaries of efficiency, we are not only offering it with our regular, medium convexity base, but also in specialised High Base Convexity (HBC) and Low Base Convexity (LBC) variants that enable customers to edge out an extra degree or two in specific use cases. At the same time, the standard medium base convexity version will offer customers the same future-proof versatility as other Noctua multi-socket coolers and, most importantly, provides optimal results both on AM5 with the included offset mounting, on LGA1851 (RL-ILM) and on LGA1700 with the included NA-ISW1 shim washers for reducing ILM pressure. When using AM5 CPUs without the offset mounting, other flat CPUs or Intel LGA1700 CPUs with full ILM pressure, the standard version still provides solid results but will yield a degree or two compared to the HBC and LBC variants that have been optimised for these scenarios:

Thermal performance implications: What gains to expect from using HBC or LBC?

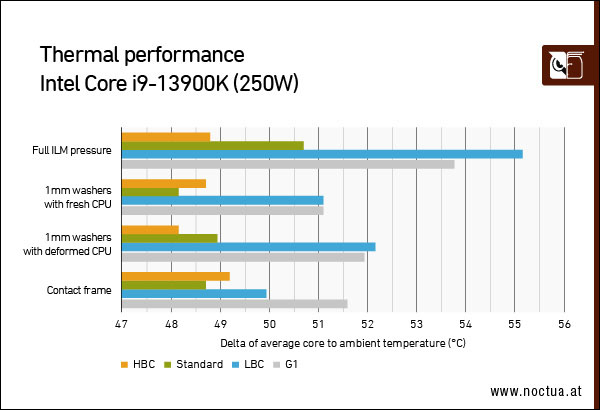

Intel LGA1700 thermals

When looking for the best possible performance on LGA1700, it’s worth noting that we could obtain the absolute best results with LGA1700 CPUs when combining the regular medium base convexity version with 1mm washers underneath the ILM. This is why the regular NH-D15 G2 with medium base convexity includes a set of NA-ISW1 1mm shim washers for optimising performance on LGA1700 processors: This combination performed around 0.6°C better than the HBC version with full ILM pressure and will give customers the best possible performance with a heatsink that will, at the same time, also provide excellent results on AM5.

As can be seen from the data above, it’s when Intel LGA1700 CPUs are used with full ILM pressure or have become permanently deformed from ILM pressure that the HBC version steps in and will offer a performance benefit over the standard version: By choosing the specialised HBC version, customers can typically gain 1-2°C compared to the medium base convexity standard model on LGA1700 processors that are used with full ILM pressure.

While the HBC version’s performance is typically 0.5-1°C lower than the medium base convexity standard version on fresh CPUs with reduced ILM pressure, it also pulls ahead on CPUs that have already been deformed from longer use with full ILM pressure, even when using 1mm washers to reduce ILM pressure. Whether or not a particular CPU has become permanently deformed or not is difficult to tell since this will depend on various factors (time of use, thermal cycling, CPU and socket height, tolerances in ILM pressure, heatsink mounting pressure, heatsink contact surface, etc.), but as a rule of thumb, we tend to expect slightly better results with the HBC version on CPUs that have been used extensively for more than 3 months. In this case, it can also make sense to combine the HBC versions with the included washers.

Another important takeaway is that in our testing with HBC and regular medium base convexity coolers, the 1mm washer mod gave slightly better results than so called “contact frames” that only enabled relatively flat (LBC) coolers to perform better than with the 1mm washer mod.

Last but not least, the thermal results show that customers should definitely avoid using LBC heatsinks on LGA1700 CPUs with full ILM pressure where the performance penalty compared to HBC coolers can be more than 6°C. Using 1mm washers helps the LBC version to catch up a bit, but depending on whether the CPU is fresh or deformed, it still trails the standard and HBC versions by 2-4°C. It’s only with so called “contact frames” and fresh, non-deformed CPUs that the LBC version can be made to perform decently well on Intel LGA1700, reducing its leeway to around 1°C.

AMD AM5 thermals

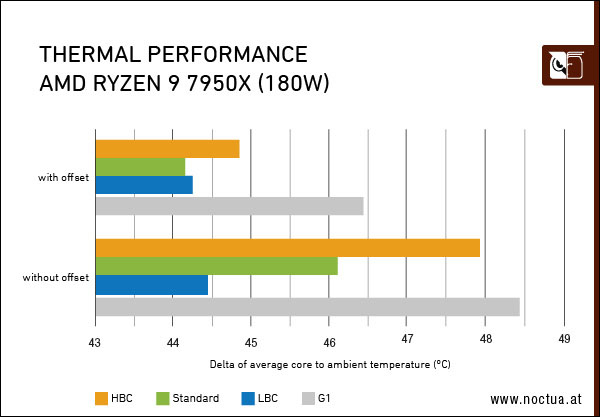

On AMD AM5, the specialised LBC version typically provides 1-2°C better performance than the standard version when used without the offset mounting. With the offset mounting, having its contact pressure centralised over the CCDs enables the standard version to perform mostly on par with or even slightly better than the specialised LBC variant that usually benefits little from an offset mount:

As can be seen from the data above, the absolute best results in our AM5 tests came from using the medium base convexity standard version with the included offset mounting. The HBC version, by contrast, typically performs 0.5-1°C lower than the regular version on AM5 when using the offset mounting and significantly (1.5 to 2°C) lower without the offset mounting. Without offset mounting, the difference between the HBC and the LBC version on AM5 can be as high as 3.5°C. However, unlike on LGA1700 where using the LBC version isn’t recommended, the performance losses when using the HBC version on AM5 can be minimised by using the offset mounting.

On other relatively flat processors such as AM4, LGA2066 and LGA2011(-3), the LBC variant can also provide benefits in the range of 1-3°C compared to the regular version. The LBC version is also recommended for use on delidded AM5 CPUs (direct die application) as well as when using flat custom heatspreaders.

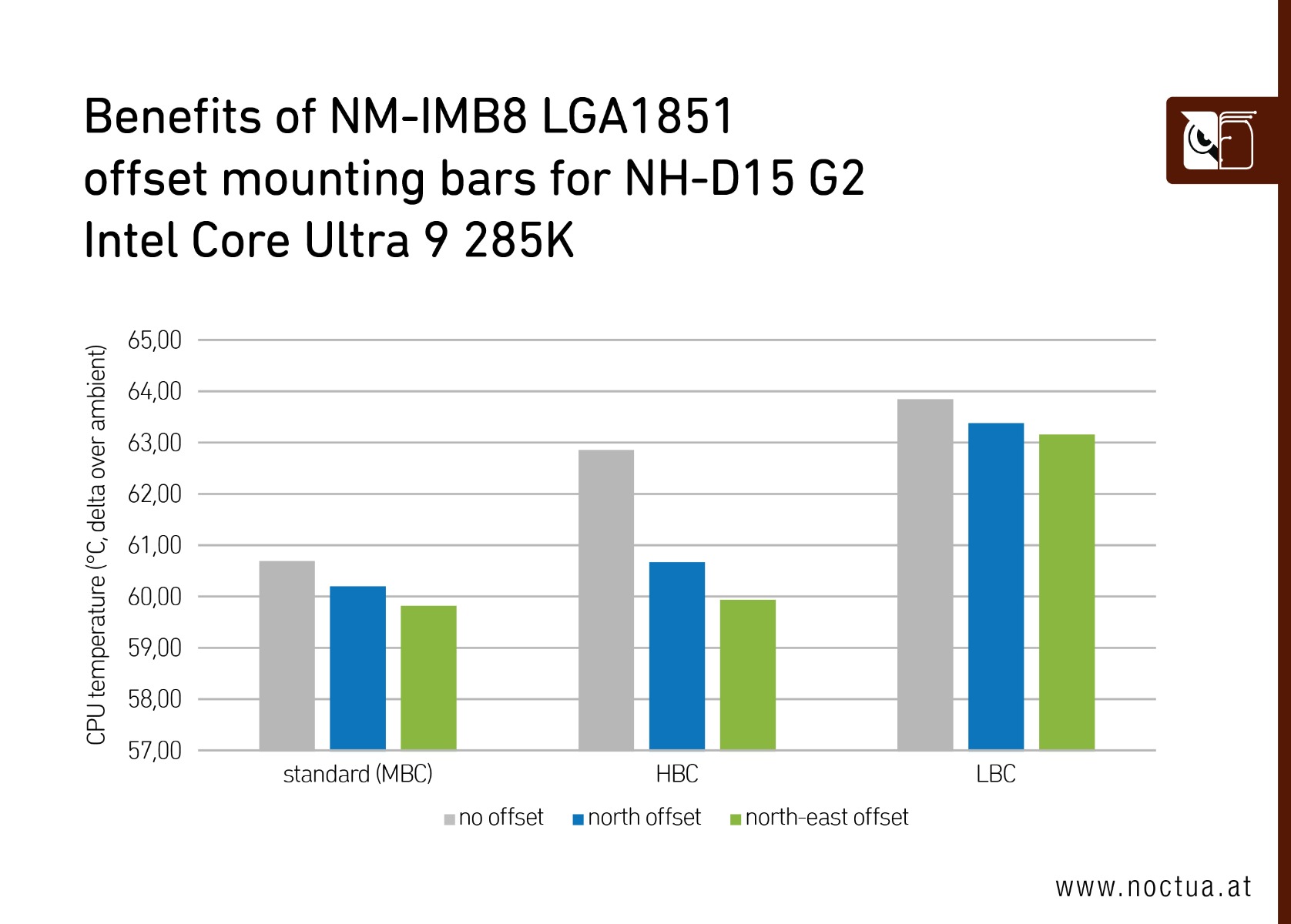

LGA1851 thermals

On LGA1851 (RL-ILM), the situation is very similar to fresh LGA1700 CPUs that are used with reduced ILM pressure: The medium base convexity standard version achieves the best results with a clear ~2°C lead over the HBC and 3°C over the LBC model. Due to the offset hotspot location of the 24-and 20-core CPUs, performance can be fine-tuned by using the optional NM-IMB8 mounting bars as described in this article. However, the gains from this offset are generally smaller than with AMD AM5 and while the HBC version benefits more (up to 3°C) than the medium convexity standard version (up to 1°C), the standard version remains the best choice for LGA1851 processors, providing the best results both with and without offset:

Conclusion: Which version to choose?

Summing up the test results, our default recommendation is the medium base convexity standard version since it provides the best results on LGA1851 (RL-ILM), on AMD AM5 with the offset mounting as well as on Intel LGA1700 with the included 1mm shim-washers unless the CPU has become permanently deformed from long-term use with full ILM pressure. Even in this case, when running Intel LGA1700 CPUs with full ILM pressure or when not using the offset mounting on AMD AM5, the standard version is guaranteed to provide solid results.

However, it’s in these cases and certain other applications that the specialised LBC and HBC versions can offer an extra 1-2°C edge, which makes them an attractive option for customers who want to get the best possible results in these particular configurations and don’t mind trading in some versatility for this. By contrast, the standard medium base convexity version is the most versatile and future-proof.

| NH-D15 G2 LBC | NH-D15 G2 (standard) | NH-D15 G2 HBC | |

|

Excellent | Good | Not recommended |

|

Excellent | Excellent | Good |

|

Good | Excellent | Good |

|

Not recommended | Excellent | Good |

|

Not recommended | Good | Excellent |

Video guide

Your opinion matters!

We are excited to invite you to participate in our short website survey. It will only take 5 minutes of your time!