G2 fan series aerodynamic innovations: the keys to their superior performance

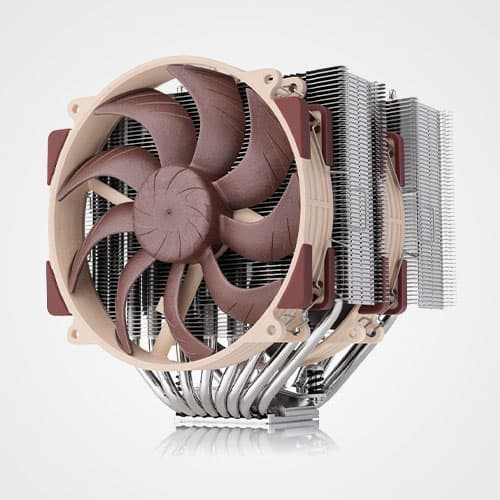

The NF-A14x25 G2 and NF-A12x25 G2 build on the technological innovations of the ground-breaking NF-A12x25 such as the use of Sterrox® LCP, an ultra-tight tip clearance and its strongly swept nine blade impeller. At the same time, the G2 models are pioneering aerodynamic innovations that further refine this design approach. In particular, the NF-A14x25 G2 and NF-A12x25 G2 are characterised by the introduction of the novel Progressive Bend impeller, the Centrifugal Turbulator hub and the addition of winglets, all of which work together in order to enable a breakthrough in airflow-to-noise efficiency compared their predecessor models.

Progressive Bend impeller

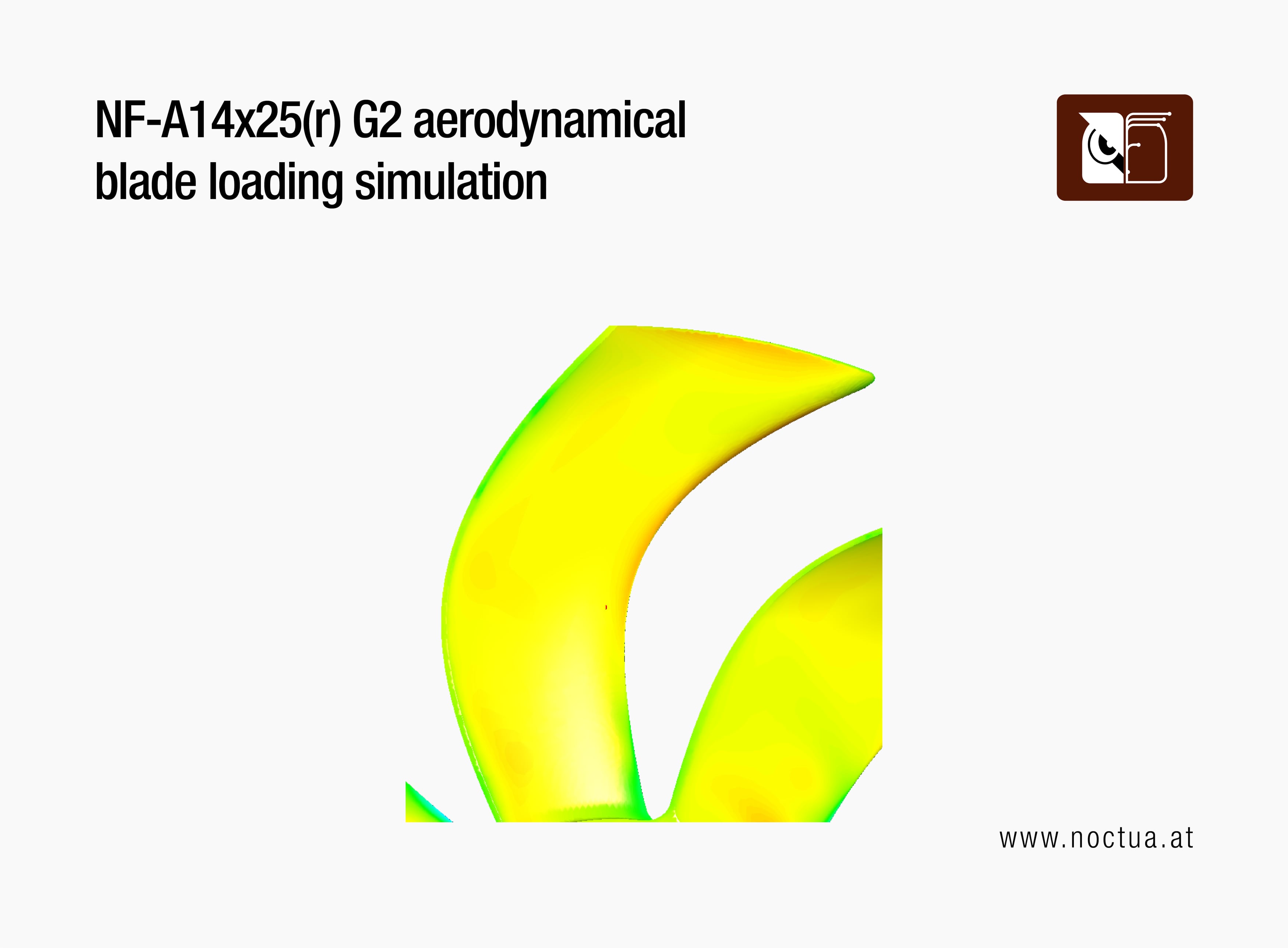

The NF-A14x25 G2 and NF-A12x25 G2 feature unique Progressive Bend impellers with Flow Acceleration Channels and winglets. Whereas the original NF-A12x25’s nine impeller blades are bent relatively continuously, the blades of the G2 models are swept backwards close to the hub and progressively bent forward further out, which results in a distinct, almost kink-like shape. Working in tandem with the Centrifugal Turbulator hub, this design not only helps to push more air towards the outer blade areas where efficiency is higher, but also assures maximum lift and near uniform loading across the entire blade span. Since the absolute speed of fan blades becomes lower and lower closer to the hub, aerodynamic performance is highest near the tips of the blades and lowest near the hub. By driving more air outwards to the higher efficiency zones, overall efficiency can be increased. However, care must be taken to maintain as even as possible loading over the entire length of the blades in order to avoid flow separation and air leaking back through the low-performance central region in applications with high back pressure such as heatsinks or radiators. The NF-A14x25 G2’s and NF-A12x25 G2’s novel Progressive Bend impellers strike a perfect balance between driving air outwards for maximum efficiency gains and keeping a near uniform loading to ensure consistent performance in high impedance applications. Last but not least, both the shape and the profile of the G2 fans’ blades have been carefully fine-tuned to enhance aerodynamic lift, which gives their P/Q curve an extra push in the critical mid-section and thereby also contributes to the fans’ superior performance on heatsinks and radiators.

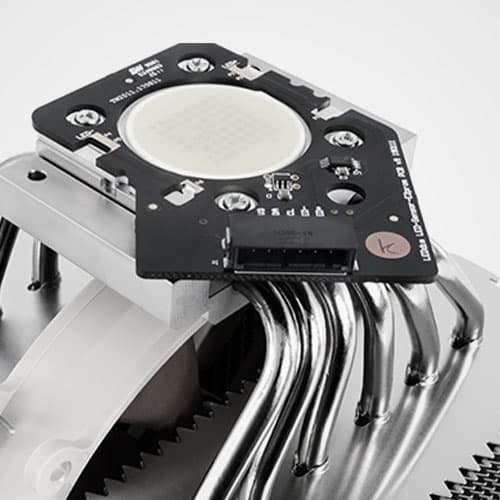

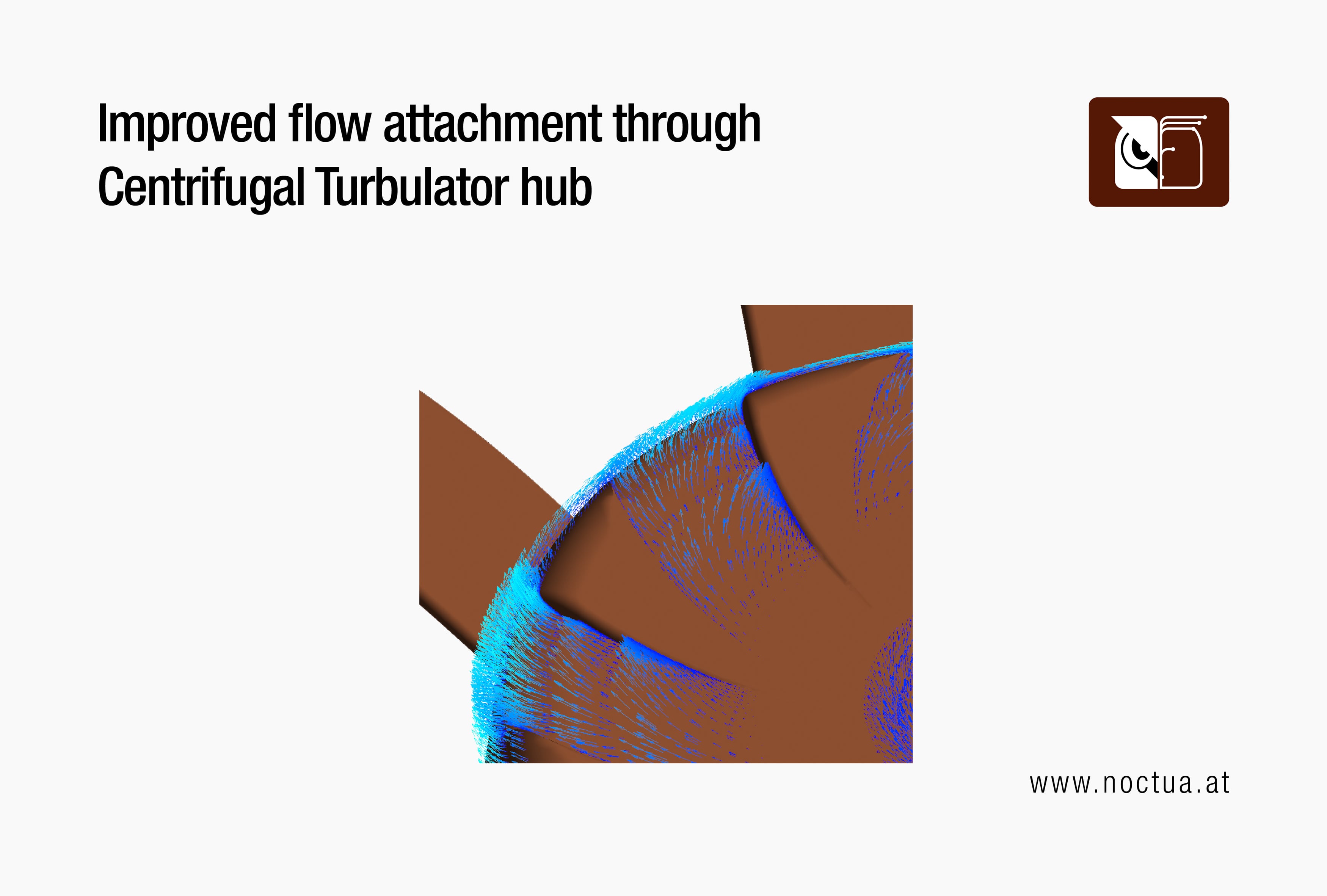

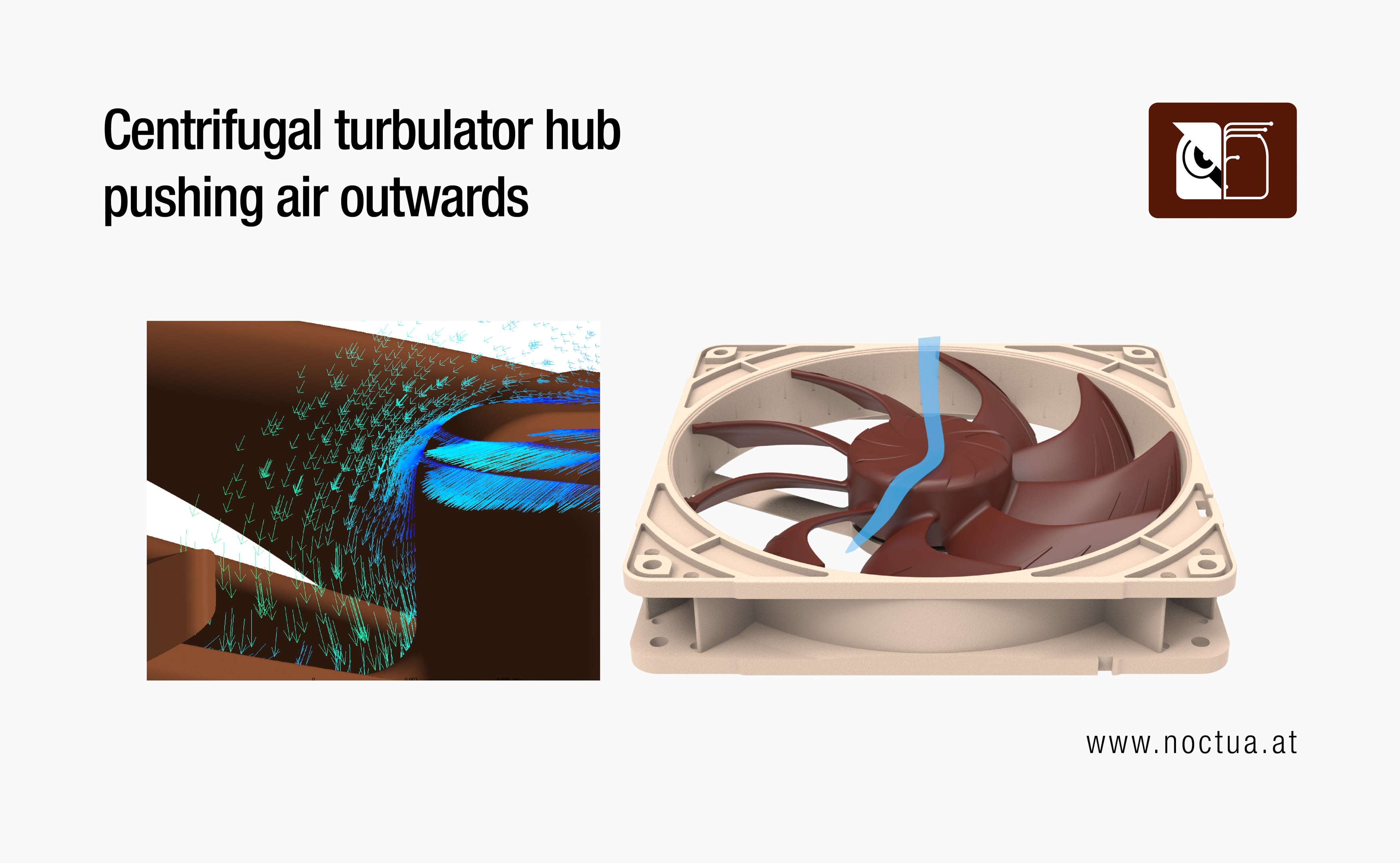

Centrifugal Turbulator hub

The second novel feature of the NF-A14x25 G2’s and NF-A12x25 G2’s impellers is the new Centrifugal Turbulator hub. By acting as a turbulator, this novel design measure improves flow attachment in the hub region, which, in return, enables the fan to draw in air more efficiently. At the same time, the centrifugal driving motion of the Centrifugal Turbulator Hub works in tandem with the Progressive Bend impeller design to push air outwards from the hub area where efficiency is low due to the slow rotational speed towards the outer, high-efficiency zones of the blades, thereby increasing overall efficiency by optimising fluid distribution across the impeller area.

Winglets

The third novel aerodynamic design measure that distinguishes the NF-A14x25 G2 and NF-A12x25 G2 impellers from the first-gen NF-A12x25 is the addition of winglets. Generally, winglets can help to reduce tip vortices that are caused by the pressure differential between the suction and the pressure side of the fan blades. However, using winglets also bears the risk of reducing efficiency due to extra fluid displacement in high velocity regions, which can often outweigh the benefits of reducing tip vortices. Navigating through these challenges, the small winglets of the G2 fans have been carefully honed to provide consistent efficiency gains and to act in concert with the Progressive Bend blade geometry, Flow Acceleration Channels and the AAO frame. In addition to its aerodynamical innovations, the NF-A14x25 G2 and NF-A12x25 G2 are also the first fans to use Noctua’s next-generation etaPERF™ motor as well as the new SupraTorque™ feature, both of which also contribute to their superior performance. Please follow the links to learn more about these features:

Related articles

Want to know more on this topic? Explore relevant articles and resources.

Sterrox® liquid-crystal polymer (LCP)

Sterrox® LCP minimizes impeller creep, dampens vibrations, and improves acoustic performance, making Noctua fans quieter and more efficient.

Flow Acceleration Channels

Flow Acceleration Channels speed up airflow at blade edges, reducing flow separation, vortex noise, and improving airflow efficiency.

NF-A12x25: interview with Lars Strömbäck (Noctua CTO)

The NF-A12x25 took over four years to develop, pushing Noctua’s R&D to new heights. Noctua’s CTO shares the innovations that make it a breakthrough in fan design.

NF-A12x25: technical backgrounds and manufacturing challenges

From material limitations to microscopic tolerances, the NF-A12x25 was one of Noctua's most challenging projects to date. But how did they overcome these obstacles?