SSO bearing

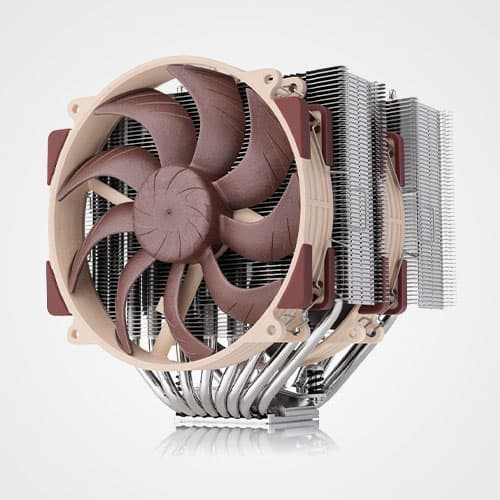

SSO-Bearing

Thanks to an optimised principle of operation, the self-stabilising oil-pressure bearing (SSO bearing) surpasses current types of ball, sleeve or liquid bearings in terms of long-term stability and quietness.

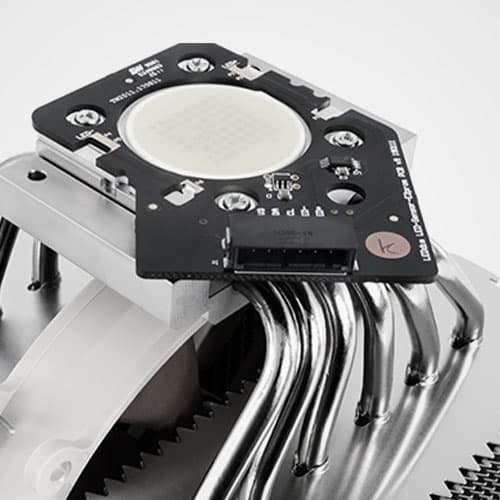

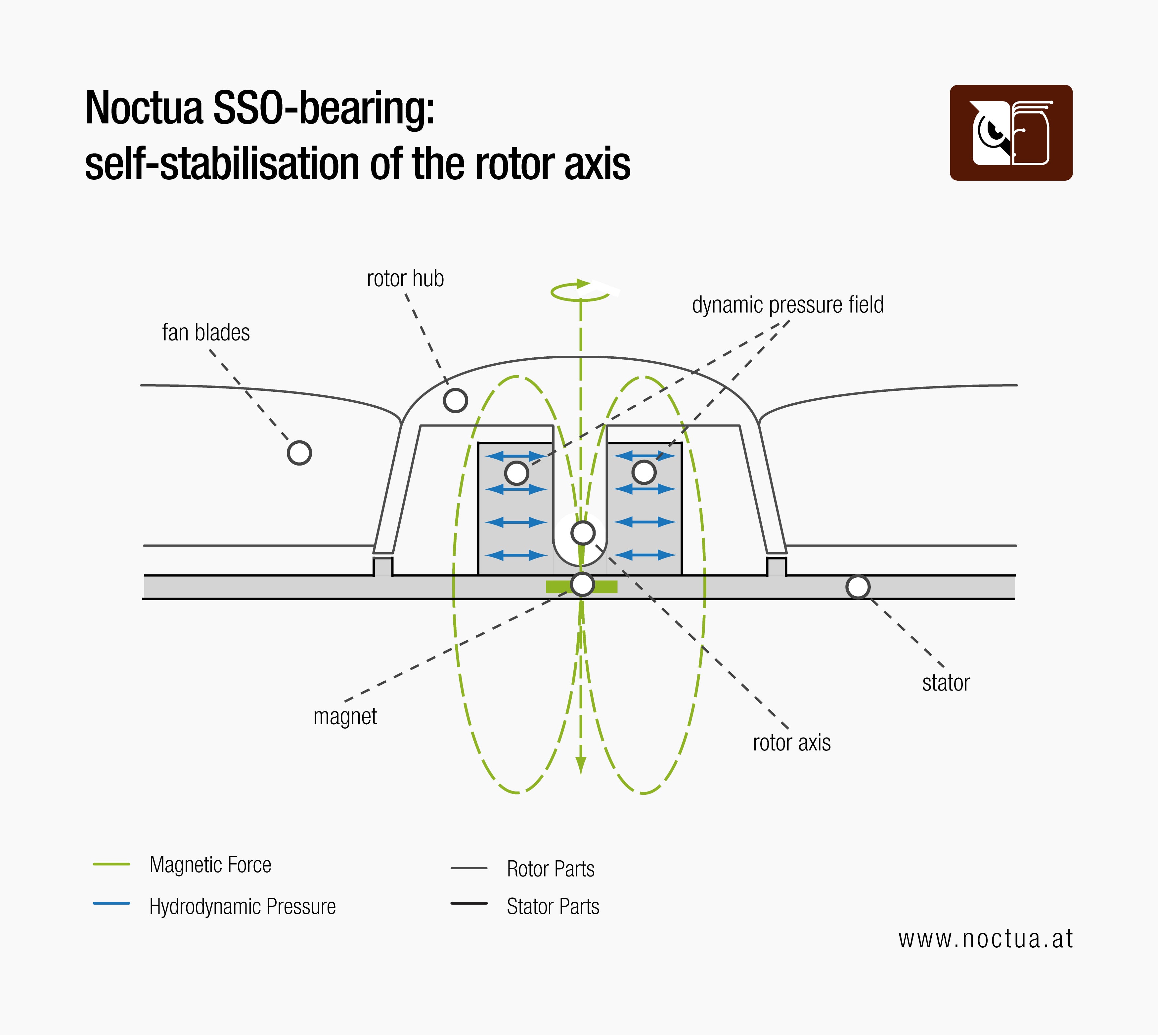

SSO principle of operation

The rotary motion of the axis generates pressure upon the special oil enclosed within the bearing. This causes the build-up of a dynamic pressure field that centres and stabilises the axis within the bearing shell. While conventional liquid bearings employ the principle of hydrodynamic pressure too, the SSO bearing is equipped with an additional magnet that supports the self-stabilisation of the rotor axis. This allows for a faster, more precise and more reliable centring of the rotor axis and thus increases the long-term stability and quietness of the bearing: When the fan starts, the dynamic pressure field of the liquid bearing needs to build up first, which results in an initial precession of the axis, the so called gyro effect. This amounts to an increased abrasion until the axis is stabilised through the build-up of the dynamic pressure field, which may by and by lead to increased noise emission and bearing defects. Because of this, the SSO bearing possesses a built in magnet, whose field ensures the immediate self-stabilisation of the rotor and hence reduces the gyro effect. In addition to the stabilisation during the start-up phase of the fan, the supporting magnet allows for a more exact centring of the axis within the bearing shell and thus further reduces bearing resistance, abrasion and noise emission.

- SSO compared to conventional sleeve and ball bearings

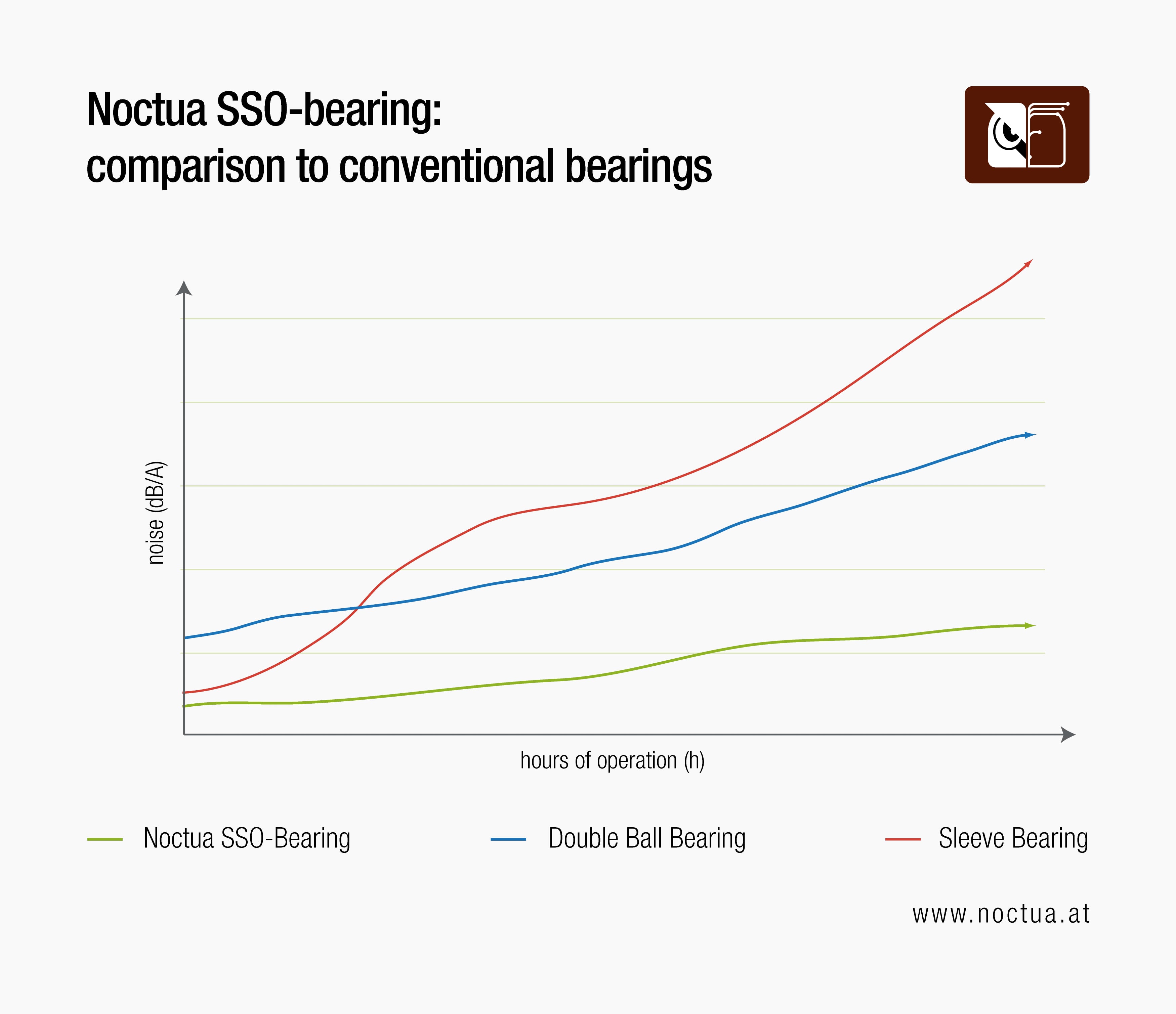

The sleeve and ball bearings currently predominating the fan market exhibit major drawbacks: While conventional sleeve bearings initially have very low noise emissions, they mostly possess unsatisfying long-term stability, which leads to a short overall lifespan and increasing noise after longer operating times. High grade ball bearings, on the other hand, while providing satisfying long-term stability operate at slightly higher noise levels from the beginning. The SSO bearing not only surpasses the quietness of conventional sleeve bearings but also the long-term stability of current top-of-the-line ball bearings.

Related articles

Want to know more on this topic? Explore relevant articles and resources.