Sterrox® liquid-crystal polymer (LCP)

Sterrox® liquid-crystal polymer (LCP)

Sterrox® is a novel liquid-crystal polymer (LCP) type material that has much better dimensional stability and less creep as compared to conventional engineering thermoplastics such as ABS, PA, PBT or PC. The name Sterrox® is derived from the Greek word στερρός, which means stiff, firm, solid, hard or rugged.

Liquid crystal polymers possess remarkable chemical and mechanical properties, such as high tensile strength and environmental inertia, that make them ideal for high-end medical and military applications with demanding requirements and budgets that can support the high material cost (roughly four times as high as PBT). The most well-known LCP is Kevlar, which is being used in products such as bulletproof vests, combat helmets and other body armour due to its excellent strength-to-weight ratio.

The remarkable mechanical rigidity of LCP materials is due to their unique molecular structure: unlike conventional polymers, which have a chaotic molecular chain orientation both in solid form and in the melt phase, thermotrophic LCPs such as Sterrox® show an ordered, rod-like molecular alignment even in the melt phase and solidify into a highly oriented, extremely rigid chain structure, which gives them much more advanced mechanical properties.

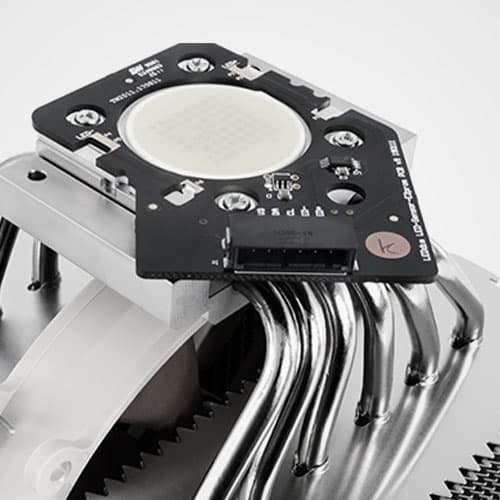

Sterrox® is Noctua’s own customised type of fibre-glass reinforced LCP that has been specifically fine-tuned for use in next-generation fan designs such as the NF-A12x25. Its extreme tensile strength, exceptionally low thermal expansion coefficient, high environmental inertia and excellent dimensional stability have made it possible to reduce impeller creep phenomena to levels that were previously unthinkable with PBT- or PA-based impellers.

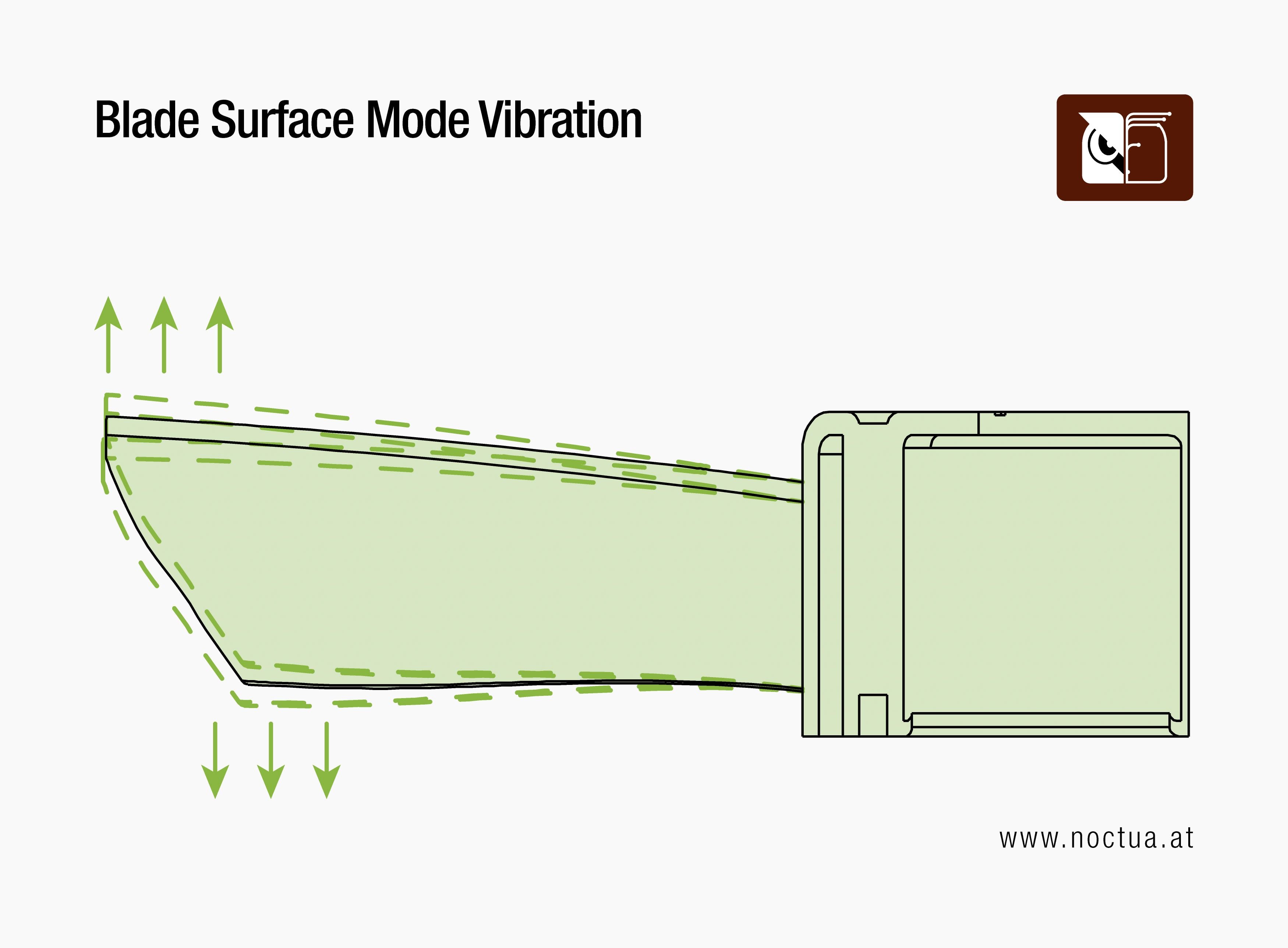

In addition to permitting fan designs with much lower tip clearances, Sterrox® provides a second key advantage in having an elasticity modulus and damping properties that are ideal for reducing resonance and vibration phenomena in advanced fan blade designs such as the NF-A12x25. In particular, the use of Sterrox® allows the suppression of a phenomenon called blade surface mode vibration: a fan impeller has a natural frequency and multiple resonant modes. When the fan is running, the turbulent air around the fan blades will transfer vibration energy into the blades and cause resonant vibrations.

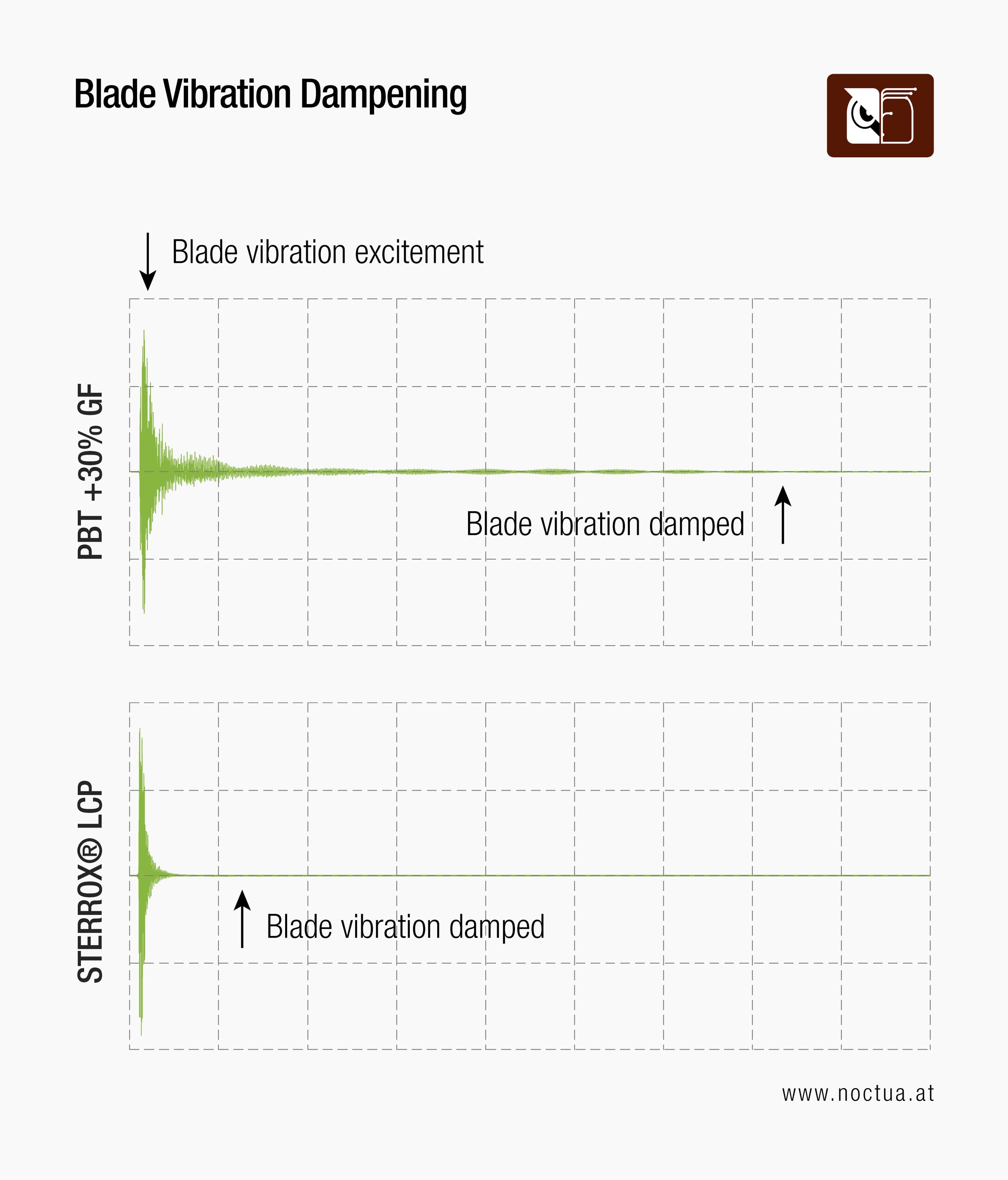

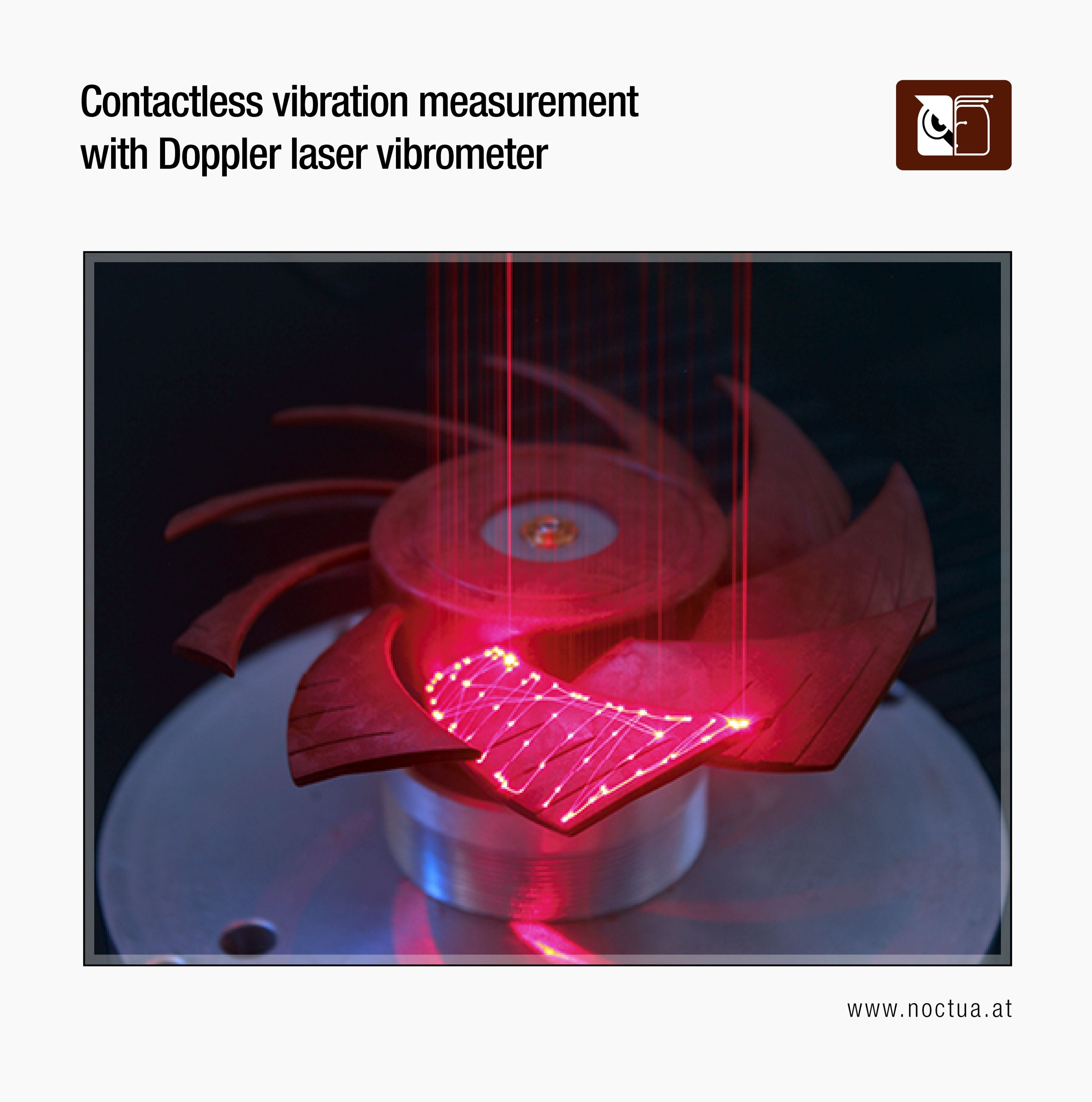

These surface vibrations are so minute that they are not critical from a mechanical point of view (unlike e.g. vibrations due to imbalance), but they can cause serious acoustic problems. The reason for this is that when the fan is running, there is a pressure difference between the intake and the outlet side of the fan (lower pressure on the upside of the blades, higher pressure on the downside of the blades). From an aero-acoustic point of view, this situation is similar to a stereo speaker where there is higher pressure inside the chassis and lower pressure outside the chassis. In both cases, the pressure difference leads to an efficient acoustic coupling, so the surface vibration of either the blades of the fan or the membrane of the speaker is transferred to the air. While this acoustic effect is desirable in the case of the speaker, avoiding it is crucial for fine-tuning the sound signature of advanced fan blade designs and this is where the increased stiffness and improved dampening properties of the Sterrox® LCP material come in: when comparing the same fan blade design made from PBT and Sterrox® and measuring their surface vibrations with a contactless Doppler laser vibrometer, the Sterrox® impeller dampens the same vibration excitement much quicker.

In real-world usage, this means that less vibration from air turbulence is transferred to the fan blades and, consequently, fewer surface mode vibrations are transferred back to the air as noise, which significantly contributes to the NF-A12x25’s smooth acoustic profile.

Related articles

Want to know more on this topic? Explore relevant articles and resources.

Our G2 fans’ aerodynamic innovations: keys to superior performance

Building on the technological innovations of the NF-A12x25, the G2 models represent a further refined, second-generation implementation of this design approach.

Flow Acceleration Channels

Flow Acceleration Channels speed up airflow at blade edges, reducing flow separation, vortex noise, and improving airflow efficiency.

NF-A12x25: interview with Lars Strömbäck (Noctua CTO)

The NF-A12x25 took over four years to develop, pushing Noctua’s R&D to new heights. Noctua’s CTO shares the innovations that make it a breakthrough in fan design.

NF-A12x25: technical backgrounds and manufacturing challenges

From material limitations to microscopic tolerances, the NF-A12x25 was one of Noctua's most challenging projects to date. But how did they overcome these obstacles?

.jpg&w=3840&q=85)